What is a Mooring Bollard?

Mooring Bollard is an important part of the mooring system. It is an anchor point that holds the mooring line to prevent the vessel from drifting away due to environmental loads such as tides, water flow and wind. It is used primarily in container and passenger terminals, general cargo and ro-ro terminals and all other types of port facilities in a simple but highly stable and efficient manner.

Different Types of Mooring Bollards

The mooring bollards are very stable to provide safe and reliable mooring. Commonly used styles of bollards are T-Head, Staghorn, Kidney, Double Bitt, Single Bitt and Pillar.

| Bollard Type | Photo | Introduce | Features |

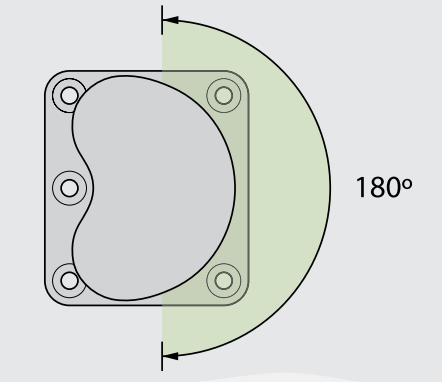

| T Head Bollard |   | T Head Bollard is also called Tee bollard or Tee-head bollard, specially designed for carrying wire ropes. This design has a “T” shaped top, hence the name. Because of its simplicity, it stands out in many parts of the world. It does well with jobs up to 300 tons and can handle higher line load angles. | • General-purpose applications up to 300 tons. • Narrow footprint for limited space installations. • Rugged and durable design, extremely low maintenance. • Suitable for a steeper rope. |

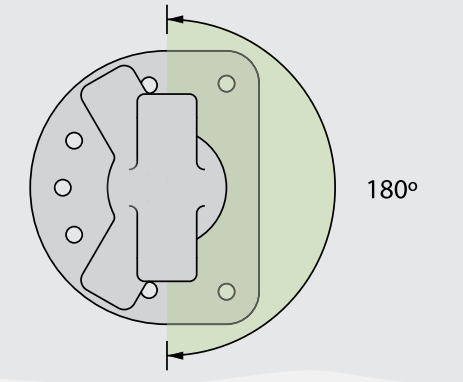

| Staghorn Bollard |   | Staghorn Bollard, also known as twin horn bollard, staghorn bitt bollard, is a direct upgrade to the traditional double bitt bollard. It is particularly suitable for applications where tidal range variations are large and can handle steep mooring line angles. | • General-purpose applications up to 250 tons. • Staghorn (or twin horn) head design to allow higher rope angle and two rope lines work. • Qualified epoxy coating with high corrosion resistance. |

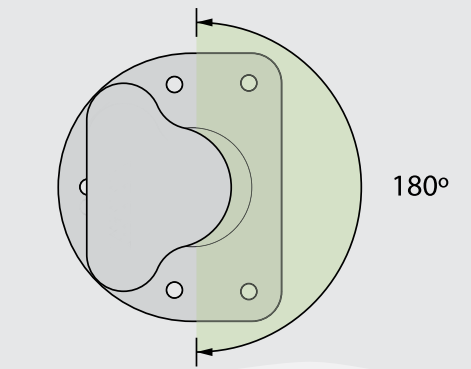

| Kidney Bollard |   | Kidney Bollard is designed with a thicker diameter at the top (head/tip of the structure) to make the mooring rope more difficult to accidentally escape. It is suitable when low to medium tidal range is expected. Kidney bollards offer an economical solution for installations where securing mooring lines at high angles is not a concern. This style is not recommended when multiple mooring lines will share one bollard. | • General-purpose applications up to 200 tons. • Ductile cast iron and cast steel materials are suitable for extreme weather. • Avoid steep rope angles where possible. • Durable design and good corrosion resistance. |

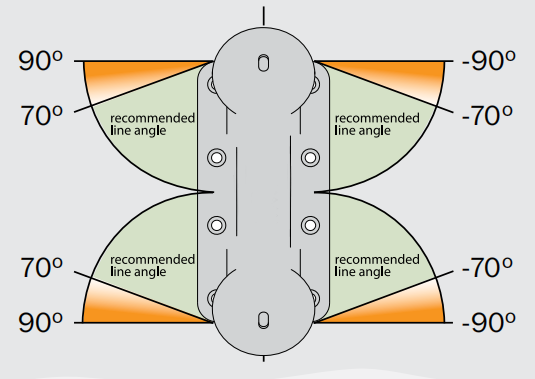

| Double Bitt Bollard |    | Double Bitt Bollard is often called twin horn bollard due to its double horn shape. It is designed with a narrow base to accommodate the limited dock space in the work area. It is useful when high densities of mooring lines are present, this is a better choice for ship mooring and shifting. | • General-purpose applications up to 200 tons. • Suitable for a lower angle. • Multiple lines could share one bollard without affecting the mooring lines of adjacent ships. • Long service life, up to 15-20 years. |

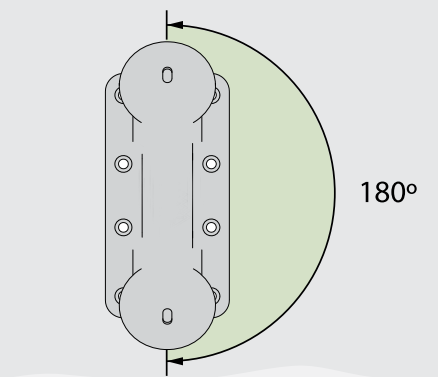

| Single Bitt Bollard |   | Single Bitt Bollard is a common mooring bollard, very often also known as pillar type bollard. It is particularly suitable for applications where tidal range variations are large and can handle steep mooring line angles. | • General-purpose applications up to 200 tons. • Multi lines may share a single bollard. • The surface is coated with rust paint with high corrosion resistance. • Suitable for steep rope angles. |

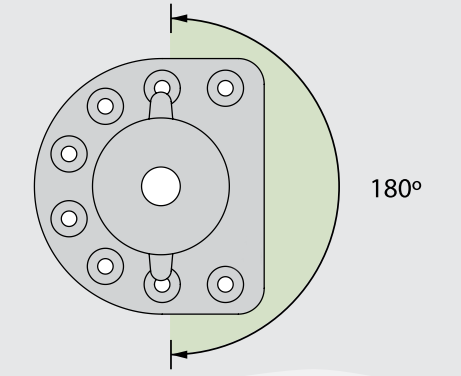

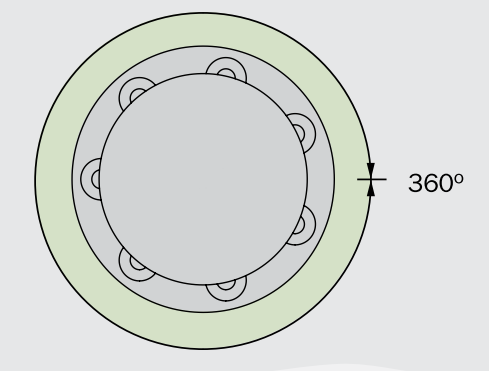

| Pillar Bollard |   | Pillar Bollard is a mooring and towing fitting installed on berth or pier to belay the mooring and towing ropes. It is normally applicable where tidal ranges are small and used for warping operations along with berths where vessels need to be re-positioned for loading purposes. Because of its 360-degree load range, it can also be placed on all sides of the pier. | • General-purpose applications up to 200 tons. • High strength and high corrosion resistance. • 360-degree horizontal line angle use. • Can be used in all directions of the pier. • Avoid steep rope angles where possible. |

How to Choose The Manufacturing Materials of Mooring Bollards?

Ductile cast iron, grey cast iron and cast steel are the most commonly used materials for the mooring bollard. All of them have their advantages during applications.

Ductile cast iron has superior strength and resistance to corrosion. Ductile cast iron combines the best attributes of grey cast iron and cast steel, is the preferred material for all bollard applications. Grey cast iron is cheaper per unit weight, but the need for thicker wall sections and poor impact strength outweighs this. Cast steel is better in cold climatic conditions. It remains popular in some countries but needs regular painting to prevent corrosion.

| Materials | Advantages | Disadvantages |

| Ductile Cast Iron | • Long service life • High strength • Good impact resistance • High corrosion resistance | The most expensive among the 3 types of materials. |

| Grey Cast Iron | • Low cost per weight • Excellent corrosion resistance | • Low strength • Low impact resistance |

| Cast Steel | • High strength • High impact resistance • Good cost per weight | Needs regular maintenance to prevent corrosion. |

Materials Specifications

| Materials | Standards | Grades |

| Ductile Cast Iron | BS EN 1563 ASTM A536 | EN-GJS-450 or 500 65-45-12 or 80-55-6 |

| Cast Steel | ASTM A148 IS 1030 | 80-50 340-570 |

| Anchor Bolts (galvanized) | ISO 898 BS 3692 ASTM | Gr 8.8 (galvanized) Gr 8.8 (galvanized) ASTM F1554 Gr 105 (galvanized) |

| Blasting (standard) Blasting (high performance) | SSPC-SP10 NACS no. 2 | SA2.5 |

| Paint (standard) Paint (high performance) | BS 3416 ISO 12944 | High build epoxy (300 microns) |

* In all cases equivalent alternative standards may apply.

* If you are still confused about the choice of materials, please feel free to contact us, and we will give you a satisfactory answer.

Surface Coating of Mooring Bollards

The mooring bollards have long exposure to a highly corrosive marine environment, which is easy to rust, so the mooring bollards require a durable coating system.

Standard available coatings including zinc oxide primers and high-performance epoxy, and can also provide hot dip galvanizing (HDG) coating according to special requirements.

Due to the wear and abrasion from the ropes, the mooring bollards need to be regularly maintained. The steel mooring bollards need to be painted often to maintain all intensity because it is more susceptible to the cast iron mooring bollards.

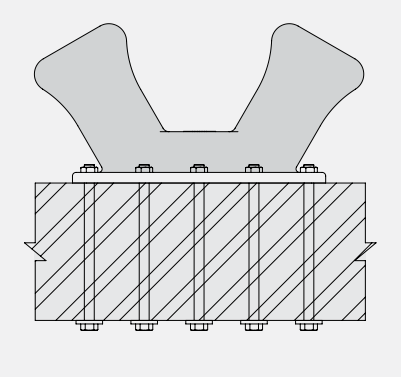

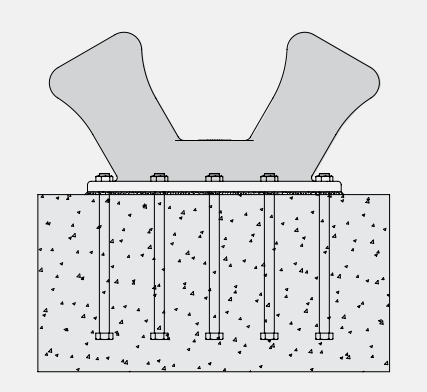

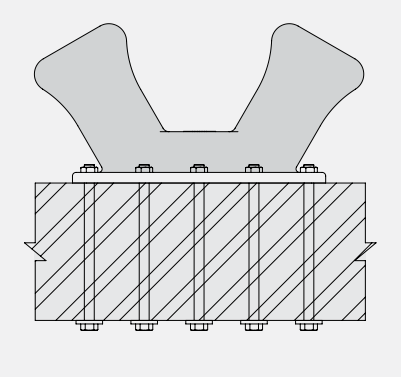

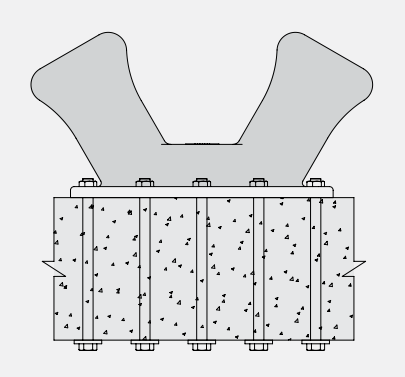

How to Install Mooring Bollards?

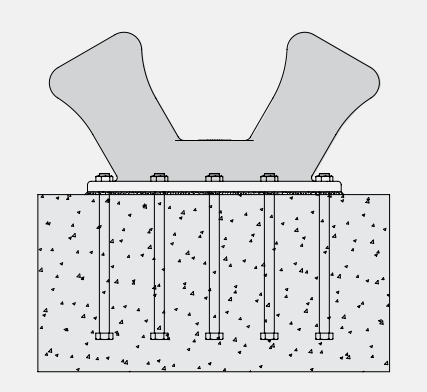

Mooring bollards must be installed correctly to obtain a long and trouble-free service life. Anchor bolts should be installed accurately using a bolted template formwork. Once the grout has reached maximum strength, the anchor bolts can be tightened to the design preload. Adhesives are often used around exposed threads to facilitate future removal. Where possible, embedding the bollard in concrete is more beneficial than surface mounting.

Bollard Fixing Options Include:

What Are The Maintenance Requirements of Mooring Bollards?

Like all equipment in the marine environment, regular inspection and maintenance are critical to achieving mooring bollards’ maximum life expectancy.

- Cleaning

Since ships that are generally applied at sea can host some sea shellfish and microorganisms, mooring posts need to be cleaned and attention should be paid to cleaning these microorganisms regularly.

- Reinforcement

In daily use, the mooring posts will be pulled by the cable, resulting in a very high possibility of loosening under the action of long time tension. Pay attention to the reinforcement requirements and check the tightness periodically to ensure stability.

- Grout

Regular inspection and possible repair of grout under and around the bollard are critical to the ongoing integrity of bollard’s performance. Replacement is recommended should grout be cracked or damaged.

- Protective Coating

Wear and abrasion from ropes mean paint coatings need regular maintenance. Like all epoxy coating systems, maintenance is integral to increasing life expectancy. We recommend regular inspection of the bollard’s surface coating.

Conclusion

Mooring bollards play an important role in ship mooring. It is increasingly popular with customers due to its high-performance marine mooring use. As a professional marine equipment supplier, Boomarine provides high-quality and inexpensive marine bollards. In addition, we can also provide customized mooring bollards according to customer requirements. If you have any needs, please feel free to contact us.