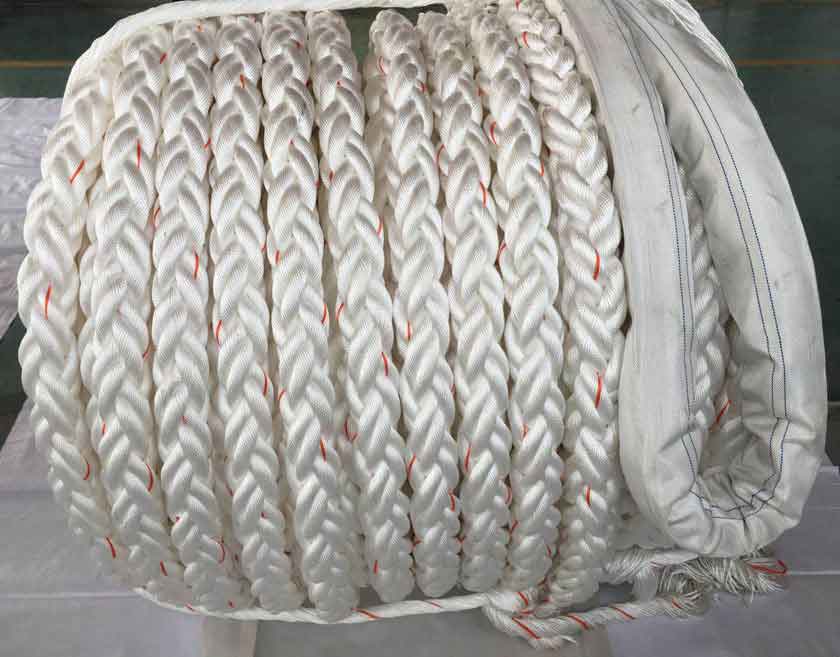

PP/PE (Polypropylene &Polyethylene) Mixed Rope is made of special high-quality mixed PP/PE (Polypropylene/Polyethylene) fiber and widely used worldwide for its high performance and competitive price. The mixed PP/PE rope is with 30% higher MBL than normal PP rope, and it’s also with better abrasion resistance, UV resistance, and longer service life.

Instead of traditional nylon rope, it is good for water retention, and easy to use. Good wear resistance, seawater corrosion resistance, high strength, anti-static, and long service life.

As a professional marine equipment supplier, Boomarine provides various series of mooring ropes such as polyamide, polyester, polyethylene, polypropylene, high molecular weight polyethylene, and nylon. They have a 3-layer, 4-layer, 6-layer, 8-layer, 12-layer, 24-layer and double-layer structure, with a diameter of 4 to 160 mm. Mooring ropes are widely used in shipbuilding, ocean transportation, ocean operations, national defense and military industry, and port terminals. We comply with ISO 9001:2000 certification guidelines, and all our products have passed CCS, GL, BV, NK, ABS, LR, DNN and RS certifications. If you are interested in our products, please feel free to contact us.

Features of Mixed PP & PE Rope

- Twisted pair structure

- Easy to handle

- Has excellent wear resistance

- Optimal strength-to-weight ratio

- Good resistance to friction and heat damage

- High temperature resistance than ordinary cable

- Good UV resistance

- Excellent chemical resistance

- Excellent reloading ability

Applications of Mixed PP & PE Rope

- Port towing

- Oil tanker

- Asphalt ship

- Ocean fishing

- Large bulk cargo ship

- Ocean engineering

- Chemical ship

- Moorings, anchors and towlines

Specification of Mixed PP & PE Rope

|

SPECIFICATION – 8 STRAND & 12 STRAND |

|||||||

|

Size |

Weight |

Breaking Strength |

Breaking Strength |

||||

|

mm Dia. |

Inch Cir. |

g/m |

kg/220m |

KN |

Ton |

KN |

Ton |

|

24 |

3 |

274 |

60.3 |

118 |

12 |

106 |

10.8 |

|

28 |

3-1/2 |

372 |

81.8 |

155 |

15.9 |

140 |

14.3 |

|

32 |

4 |

487 |

107.1 |

192 |

19.6 |

173 |

17.6 |

|

36 |

4-1/2 |

618 |

136 |

240 |

24.5 |

216 |

22.1 |

|

40 |

5 |

762 |

167.6 |

300 |

30.6 |

270 |

27.5 |

|

44 |

5-1/2 |

920 |

202.4 |

357 |

36.4 |

321 |

32.8 |

|

45 |

5-5/8 |

968 |

213 |

371 |

37.9 |

334 |

34.1 |

|

48 |

6 |

1092 |

240.2 |

415 |

42.3 |

374 |

38.1 |

|

50 |

6-1/4 |

1195 |

262.9 |

453 |

46.3 |

408 |

41.6 |

|

52 |

6-1/2 |

1281 |

281.8 |

492 |

50.2 |

443 |

45.2 |

|

55 |

6-7/8 |

1445 |

317.9 |

535 |

54.6 |

482 |

49.2 |

|

56 |

7 |

1491 |

328.0 |

550 |

56.1 |

495 |

50.5 |

|

60 |

7-1/2 |

1711 |

376.4 |

635 |

64.8 |

571 |

58.3 |

|

64 |

8 |

1953 |

429.7 |

710 |

72.4 |

639 |

65.2 |

|

65 |

8-1/8 |

2018 |

444.0 |

732 |

74.7 |

659 |

67.3 |

* MBF: Mini? Breaking Force according to ISO2307.

* LDBF: Line Design Break Force according to OCIMF MEG4 appendix B

* Other sizes are available upon request

What are Polyolefin Fibers?

Polyolefin is a type of polymer with the general formula (CH2CHR)n. They are derived from a handful of simple olefins ( alkenes). In the commercial sense, Polypropylene (PP) and polyethylene (PE) are the main used Polyolefin fibers.

Polypropylene Fiber Features:

1. Light weight

The density of polypropylene fiber is 0.90-0.92 g/cm3, which is the lightest among all chemical fibers. It is 20 percent lighter than nylon, 30 percent lighter than polyester, and 40 percent lighter than viscose fiber.

2. High strength, good elasticity, wear resistance, corrosion resistance

Polypropylene has high strength (the same in dry and wet states), which is the ideal material for making fishing nets and cables. Good wear resistance and resilience, strength is similar to polyester and nylon, rebound rate can be comparable to nylon, wool, much larger than polyester, viscose fiber; Polypropylene has poor dimensional stability, easy to pilling and deformation, anti-microbial, no decay; Chemical resistance is better than ordinary fiber.

3. With electrical insulation and warmth

Polypropylene fiber has high resistivity (7×1019 ω.cm) and low thermal conductivity. Compared with other chemical fibers, polypropylene fiber has the best electrical insulation and heat preservation, but it is easy to produce static electricity during processing.

4. Poor heat resistance and aging resistance

The melting point of polypropylene fiber is low (165~173?), and the stability of light and heat is poor, so the heat resistance and aging resistance of polypropylene fiber are poor, and it is not resistant to ironing. But the anti-aging property can be improved by adding an anti-aging agent during spinning.

5. Poor hygroscopicity and dyeing

The hygroscopicity and dyeing properties of polypropylene fiber are the worst in chemical fiber, with almost no hygroscopicity, and its moisture regain rate is less than 0.03%. Fine denier polypropylene fiber has strong core absorption, water vapor can be eliminated through the capillary in the fiber.

The dyeing property of pp is poor, the color is light, and the dyeing fastness is poor. Ordinary fuel can not make it dyeing, most of the colored POLYPROPYLENE fiber is produced by spinning before coloring. It can be colored with raw liquid, modified with fiber, and mixed with fuel complexing agent before melting spinning.

Polyethylene Fiber Features:

- Polyethylene fiber strength and elongation are close to polypropylene fiber.

- Hygroscopicity is similar to PP, and moisture regain is 0 under normal atmospheric conditions.

- It has more stable chemical properties, has good chemical resistance and corrosion resistance.

- Poor heat resistance, but good moisture and heat resistance.