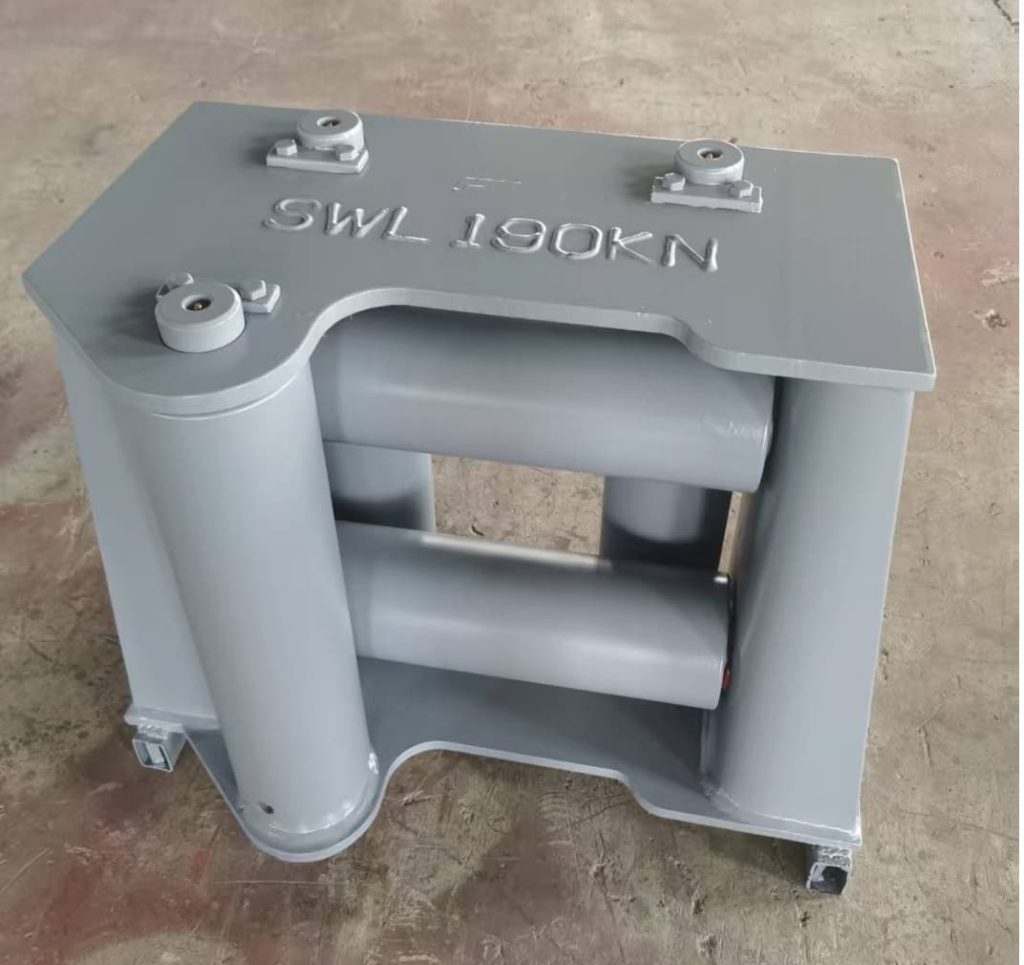

ISO 13776 Pedestal Fairlead

- Standard: ISO 13766

- Material: Weldable steel plates

- Roller No.: Single Roller

- Nominal Size: 150mm to 500mm

- Weight: 55kg – 938kg

- SWL: 265KN to 1942KN (θ=90°), 186KN to 1373KN (θ=0°)

- Surface Treatment: Sandblasting to S2.5 + one layer of epoxy shop primer, Galvanized, Polished, customized surface treatment available.

- Certificate: ABS, BV, CCS, DNV, LR, NK, RINA, etc.

As with other components of a vessel, the ISO 13776 Pedestal Fairlead stems from an intellectual design process and is produced within the framework of International Standards Organization (ISO) rules on mooring accessories. This through-deck fairlead facilitates the significant reduction in frictional forces when a vessel’s lines are pulled through sheaves on the upper rollers by providing rotary slipping connections that reduce wear.

ISO 13776 Pedestal Fairlead can easily be mounted onto decks or mooring buoys and also comprises vertical cylindrical supports to ensure stability while rotatable rollers regulate line movement, thus serving as a fairlead. Its application extends aloof deck and quay vessels both in commercial shipping as well as offshore industries including global maritime facility hubs.

As a leading marine equipment supplier in China, Boomarine offers a wide range of types of fairleads and can provide tailor-made solutions for each customer. In addition to the ISO 13776 standard, we also offer other certifications such as ABS, BV or DNV, which can give you additional peace of mind.

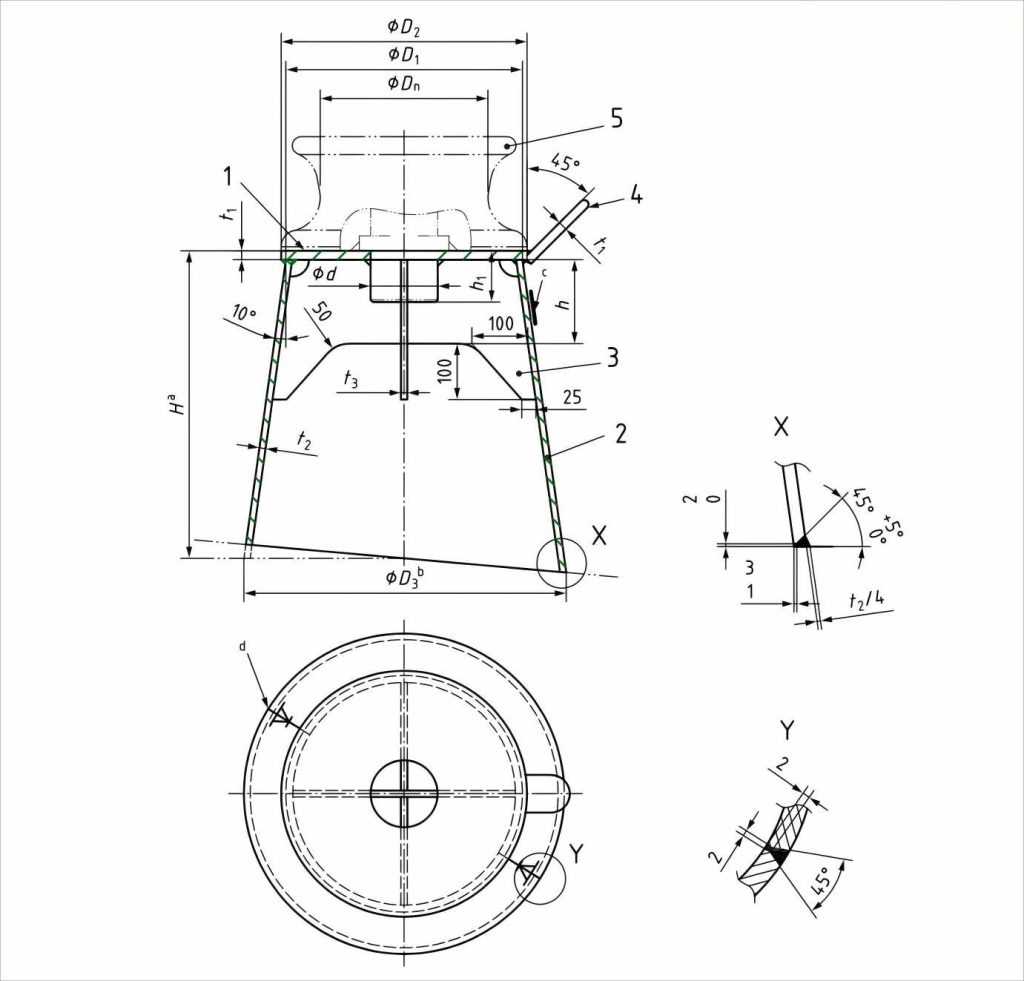

Dimensions of ISO 13776 Pedestal Fairlead

Key Structures

1. top plate

2. body

3. reinforcement

4. rope guide

5. steel roller (IS0 13755 steel rollers)

a. Height is to be determined in accordance with actual mooring rope height through the pedestal fairlead.

b. Diameter ∅D, is to be calculated depending on the height of the pedestal, H [D3= D2 + 2 x (H – t1) x tan 10°]

c. SWL marking

d. Seam

| Table 1—Dimensions of ISO 13766 pedestal fairleads | |||||||||||

| Dimensions in millimetres | |||||||||||

| Nominal size Dn | D₁ | D₂ | de | h | h₁ | t₁ | t2 | t₃ | Welding leg lengtha | ||

| Type A and B | Type C | Z1 | Z₂ | ||||||||

| 150 | 220 | 230 | 71,5 | 81,5 | 200 | 100 | 16 | 10 | 16 | 8 | 5 |

| 200 | 288 | 300 | 93,5 | 102,5 | 200 | 100 | 20 | 12 | 20 | 10 | 6 |

| 250 | 357 | 370 | 113,5 | 119,5 | 200 | 100 | 22 | 12,5 | 22 | 11 | 6 |

| 300 | 417 | 430 | 128,5 | 130,5 | 225 | 125 | 24 | 13 | 24 | 12 | 6,5 |

| 350 | 472 | 490 | 145,5 | 152,5 | 225 | 125 | 26 | 17 | 26 | 15 | 8,5 |

| 400 | 540 | 560 | 154,5 | 164,5 | 250 | 150 | 28 | 18 | 28 | 17 | 9 |

| 450 | 600 | 620 | 167,5 | 179,5 | 250 | 150 | 30 | 20 | 30 | 20 | 10 |

| 500 | 655 | 680 | 178,5 | 195,5 | 250 | 150 | 32 | 22 | 34 | 23 | 11 |

| Table 2—Dimensions (continued) and SWL of ISO 13766 pedestal fairleads | |||||||

| Dimensions in millimetres | |||||||

| Nominal size Dn | SWLC | Calculated weightd kg (for reference only) | |||||

| θb=90° | θ=0° | ||||||

| kN | t | kN | t | H=500 | H=1000 | H=1500 | |

| 150 | 265 | 27 | 186 | 19 | 55 | 115 | 198 |

| 200 | 441 | 45 | 314 | 32 | 86 | 169 | 278 |

| 250 | 579 | 59 | 412 | 42 | 113 | 210 | 335 |

| 300 | 726 | 74 | 510 | 52 | 145 | 256 | 395 |

| 350 | 1040 | 106 | 736 | 75 | 201 | 358 | 552 |

| 400 | 1246 | 127 | 883 | 90 | 255 | 436 | 657 |

| 450 | 1599 | 163 | 1128 | 115 | 314 | 530 | 791 |

| 500 | 1942 | 198 | 1373 | 140 | 383 | 636 | 938 |

| a Welding with chamfering is available based on the same welding volume/strength. b θ is the relative angle of the ropes on the pedestal fairlead (refer to Annex A). c The”SWL” which is marked on the fitting is the maximum applicable rope tension based on a 90° (θ=90°) and a 180° (θ=0°) deflections of the rope direction by the pedestal fairlead. The SWLs shown in this table are for reference only. These are based on the loadings as mentioned in Annex A. The“SWL” which is marked on the fitting may be adjusted depending on the actual loading conditions of mooring rope under the agreement between the user and the manufacturer. d The calculated weight (mass)is for reference excluding the steel roller on the pedestal fairlead. e d shall be decided depending on the type of steel roller(Type A and B or Type C), as specified in ISO 13755. | |||||||

Features of ISO 13776 Pedestal Fairlead:

- Classification Society Certification: Classification certificates from major classification societies such as ABS, BV, CCS, DNV, LR, NK, KR, IRS, RS and RINA are available to ensure quality and compliance.

- Robust construction: It has a good strength and service life fortitude because it is composed by weldable steel plates made with a yield point of not less than 235 N/mm².

- Rugged line sheaves and mooring wins efficiency: Operational safety, wear on mooring lines, winches, and other equipment can be improved through the use of high-quality rollers or pulleys.

- 360° rotation function (optional): Rotatable rollers or bases that permit multi-directional rope adjustment are available to some models, providing the 360° rotation function as an extra option.

- Corrosion protection: Prevailing harsh weather condition protection is provided in the form of durable external coatings which reinforce protection against severe corrosion.

Applications of ISO 13776 Pedestal Fairlead:

- Commercial vessels: Cargo ships, tankers, bulk carriers and container ships.

- Passenger ships: Cruise ships and ferries.

- Offshore vessels: Supply vessels, auxiliary handling vessels (AHTS) and offshore platforms.

- Naval vessels: Various naval vessels that require reliable mooring solutions.

- Tugboats and barges: For towing and push-pull operations.

Why Select Our 13776 Pedestal Fairlead?

- Increased safety: Guarantees effective control of mooring lines, minimizes the likelihood of line damage, and enhances the safety of personnel during mooring operations.

- Increased efficiency: Enhanced smoothing and speed for processes involving mooring improves overall operational efficiency.

- Reduced maintenance costs: Safeguards excessive wear on serviceable mooring lines, replacing serviced components results in decreased costs.

- Harsh offshore operating environments are withstanding: Endures harsh working conditions while providing long-term reliability and low maintenance expenses.

- Compliance and assurance: The quality is assured through compliance with ISO 13776 standards and classification society certification guaranteeing its performance.