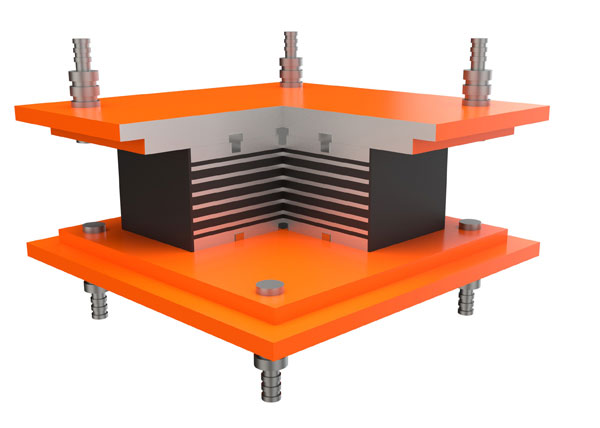

What is Laminated Rubber Bearing?

Laminated rubber bearing is composed of a multilayer stiffening plate, and steel plate all wrapped in the rubber elastic material inside and outside. The bearing has enough vertical stiffness to withstand the bridge’s internal force, and can be reliably transmitted to the pier; good elasticity and shear deformation ability by rubber materials, in order to meet the Angle and displacement of the upper structure. The damping property of rubber material can reduce the impact of dynamic load on the superstructure and pier, and play the role of buffer and isolation.

What is PTFE Sliding Bearing?

The PTFE sliding rubber bearing is a bearing formed by pasting a PTFE plate of a certain thickness on the top surface of the laminated rubber bearing. Because the friction coefficient between the PTFE plate and the stainless steel plate is very small, and the stainless steel at the bottom of the beam can slide freely, adapting to the horizontal displacement of the superstructure in a wider range.

How to Install the PTFE Sliding Bearing?

- Laminated rubber bearing should be set on support stone, support stone plane size should be calculated according to local pressure to determine the length of the pad stone, the width of the corresponding bearing size should increase about 50M, the height should be more than 100mm, and should be considered to facilitate the replacement of the bearing.

- Bearing pad stone should be arranged inside the steel mesh, reinforcement diameter is 8mm, the spacing should be 50x50m. Inside of the bridge pier, there should be vertical reinforcement extension to the bearing pad stone, the concrete strength grade of the pad stone should not be lower than C3.

- Bearing pad stone surface should be smooth, clean, dry, with no floating sand. The elevation of the top surface of the bearing pad is accurate. In the case of the flat slope, the supporting stone at both ends of the same beam and the same pier should be in the same design elevation plane, and the relative height difference of the supporting stone should not exceed ±1.5mm, and the height difference of the same supporting stone should be less than 0.5mm.

- When the bearing is installed, bias or excessive initial shear deformation should be prevented. After installation, the upper and lower parts of the support must be in close contact with each other so as to avoid cavitation. Heavy vehicles should be avoided from passing through the unintegrated beam and plate structure.

- Bridge pier design should consider support maintenance, replacement needs. In any case, two or more supports are not allowed to be installed side by side at the same support point along the longitudinal centerline of the beam; In the same beam (plate), transverse should not be set more than two bearings; Bearings of different specifications should not be installed side by side.

- After installation, the comprehensive check should be done to see if there is leakage bearing, if bearing installation direction, bearing type is wrong, if the temporary fixed facilities are demolished, whether injection of silicon fat (do not use oil instead of silicone fat) on the PTFE bearing. Once found, should timely adjust and process, to ensure the normal work of the bearings after installation, and record all deviations and anomalies after bearing installation.

With extensive experience in bridges and marine equipment, Boomarine is able to provide tailor-made solutions for the selection and installation of bridge bearings. From evaluation to supply and installation, we can provide fixed type and sliding type bridge bearing supports to meet your construction needs.