CB 3062-2011 Roller Fairlead is a common type of marine mooring and towing equipment. It is manufactured according to the CB 3062-2011 standard and consists of vertical and horizontal rollers that guide the mooring rope from any direction.

CB 3062-2011 roller fairleads are made of high-quality steel, with a diameter range of 100mm-320mm and a weight range of 112kg-2877kg, which can usually be freely mounted on the deck. Its surface is treated with zinc-rich primer and anti-rust paint, which is smooth and neat, without any defects, and has good anti-corrosion performance. It also greatly reduces the wear and tear of the rollers on the mooring ropes.

Boomarine is a professional marine equipment supplier, in addition to CB 3062-2011 standard, we can also provide roller fairleads according to JISF, DIN and GB standards. We can also customize these products according to the customer’s drawings. We also provide a series of different classification society certificates such as CCS, ABS, LR, BV, DNV, NK, etc. Please feel free to contact us if you have any requirements.

Features of CB 3062-2011 Roller Fairlead:

- Strong structure and long-lasting durability.

- Good anti-corrosion properties.

- Smooth surface to protect the mooring rope.

- Low maintenance cost.

- Lubricant filled between roller and shaft.

Parameters of CB 3062-2011 Roller Fairlead

There are 3 types of CB 3062-2011 roller fairleads: Type A, Type B, Type C. The total number of rollers varies from 3 to 5.

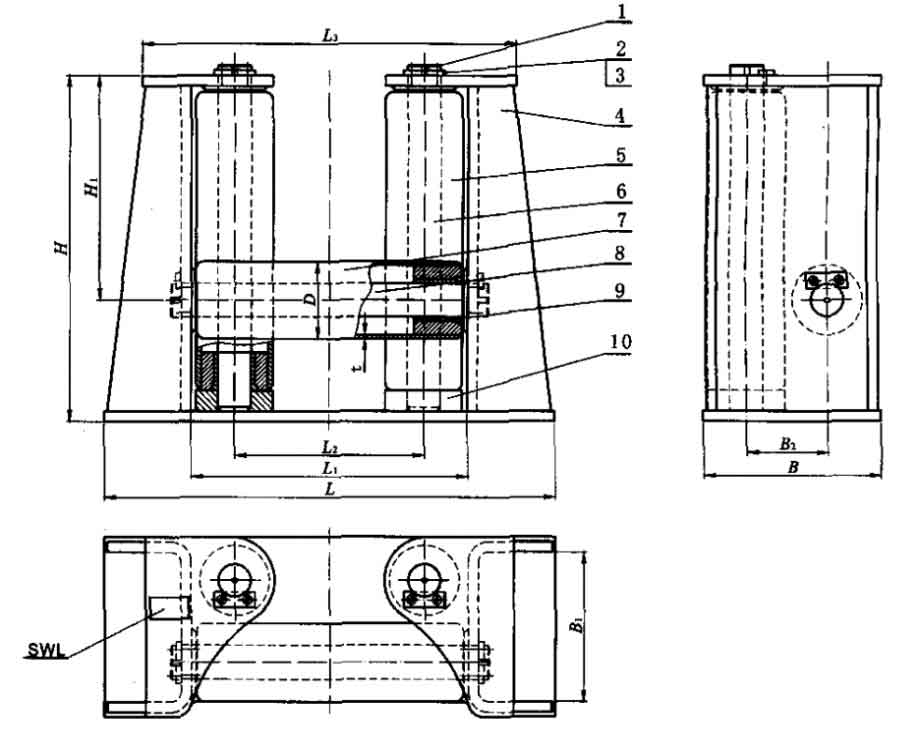

Type A

- Roller No.: 3 Rollers

- Weight: 112kg~2122kg

- Steel Cable Diameters: 14mm~44mm

- Nylon Rope Diameters: 36mm~100mm

- Oil cup

- Locking plate

- Bolt

- Frame

- Vertical roller

- Vertical shaft

- Horizontal roller

- Horizontal shaft

- Bushing

- 1Bearing for shaft

| Nominal Dia.(mm) | Steel Cable Dia.(mm) | Nylon Dia.(mm) | SWL(kN) | B | B1 | B2 | D | H | H1 | L | L1 | L2 | L3 | t | Weight(kg) |

| 100 | 14 | 36 | 54 | 238 | 194 | 108 | 102 | 508 | 330 | 644 | 416 | 300 | 544 | 10 | 112 |

| 120 | 16 | 40 | 70 | 280 | 232 | 128 | 121 | 552 | 360 | 728 | 456 | 320 | 608 | 12 | 169 |

| 140 | 18 | 45 | 89 | 304 | 250 | 138 | 140 | 606 | 405 | 776 | 480 | 330 | 646 | 14 | 227 |

| 150 | 20 | 70 | 110 | 346 | 288 | 158 | 152 | 670 | 435 | 880 | 540 | 370 | 730 | 16 | 328 |

| 160 | 22 | 80 | 133 | 370 | 308 | 168 | 168 | 710 | 470 | 940 | 580 | 400 | 780 | 18 | 388 |

| 180 | 26 | 85 | 186 | 417 | 345 | 190 | 194 | 770 | 510 | 1030 | 620 | 420 | 850 | 20 | 575 |

| 200 | 28 | 95 | 216 | 459 | 385 | 210 | 219 | 820 | 550 | 1136 | 686 | 460 | 936 | 22 | 722 |

| 230 | 32 | 100 | 282 | 521 | 445 | 240 | 245 | 910 | 605 | 1256 | 746 | 490 | 1026 | 25 | 966 |

| 260 | 36 | 100 | 357 | 590 | 500 | 270 | 273 | 1000 | 670 | 1430 | 850 | 560 | 1170 | 28 | 1422 |

| 320 | 44 | 100 | 533 | 714 | 620 | 330 | 325 | 1130 | 770 | 1690 | 990 | 640 | 1370 | 30 | 2122 |

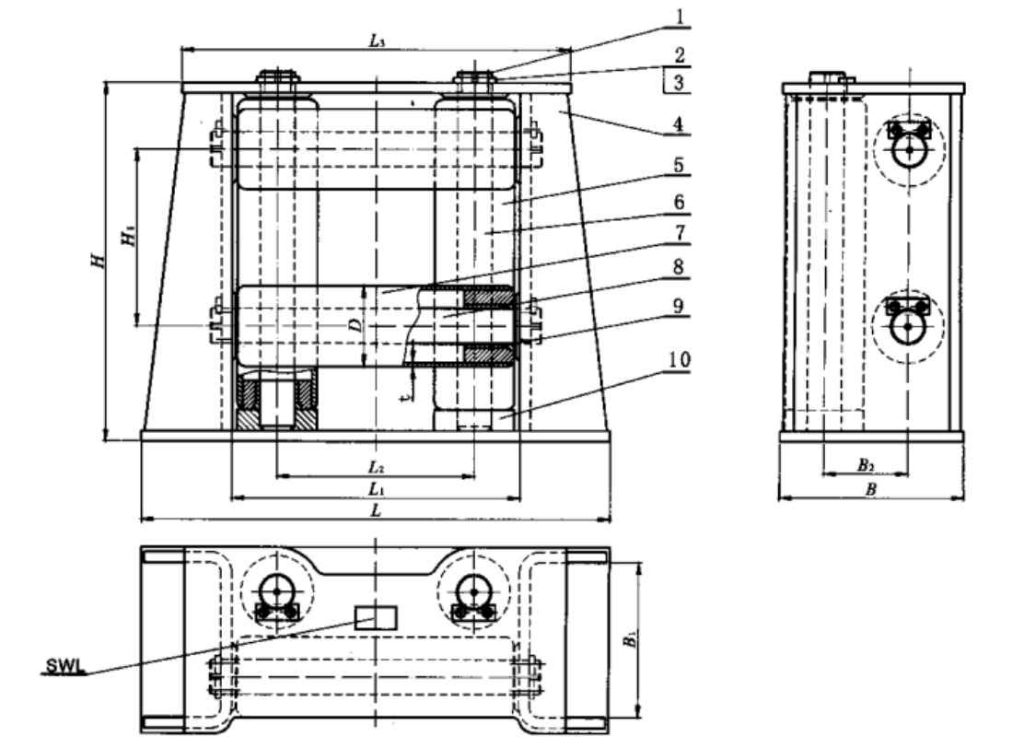

Type B

- Roller No.: 4 Rollers

- Weight: 112kg~2441kg

- Steel Cable Diameters: 14mm~44mm

- Nylon Rope Diameters: 36mm~100mm

| Nominal Dia.(mm) | Steel Cable Dia.(mm) | Nylon Dia.(mm) | SWL(kN) | B | B1 | B2 | D | H | H1 | L | L1 | L2 | L3 | t | Weight(kg) |

| 100 | 14 | 36 | 54 | 238 | 194 | 108 | 102 | 508 | 330 | 644 | 416 | 300 | 544 | 10 | 112 |

| 120 | 16 | 40 | 70 | 280 | 232 | 128 | 121 | 552 | 360 | 728 | 456 | 320 | 608 | 12 | 169 |

| 140 | 18 | 45 | 89 | 304 | 250 | 138 | 140 | 606 | 405 | 776 | 480 | 330 | 646 | 14 | 227 |

| 150 | 20 | 70 | 110 | 346 | 288 | 158 | 152 | 670 | 435 | 880 | 540 | 370 | 730 | 16 | 328 |

| 160 | 22 | 80 | 133 | 370 | 308 | 168 | 168 | 710 | 470 | 940 | 580 | 400 | 780 | 18 | 388 |

| 180 | 26 | 85 | 186 | 417 | 345 | 190 | 194 | 770 | 510 | 1030 | 620 | 420 | 850 | 20 | 620 |

| 200 | 28 | 95 | 216 | 459 | 385 | 210 | 219 | 820 | 550 | 1136 | 686 | 460 | 936 | 22 | 798 |

| 230 | 32 | 100 | 282 | 521 | 445 | 240 | 245 | 910 | 605 | 1256 | 746 | 490 | 1026 | 25 | 1067 |

| 260 | 36 | 100 | 357 | 590 | 500 | 270 | 273 | 1000 | 670 | 1430 | 850 | 560 | 1170 | 28 | 1585 |

| 320 | 44 | 100 | 533 | 714 | 620 | 330 | 325 | 1130 | 770 | 1690 | 990 | 640 | 1370 | 30 | 2441 |

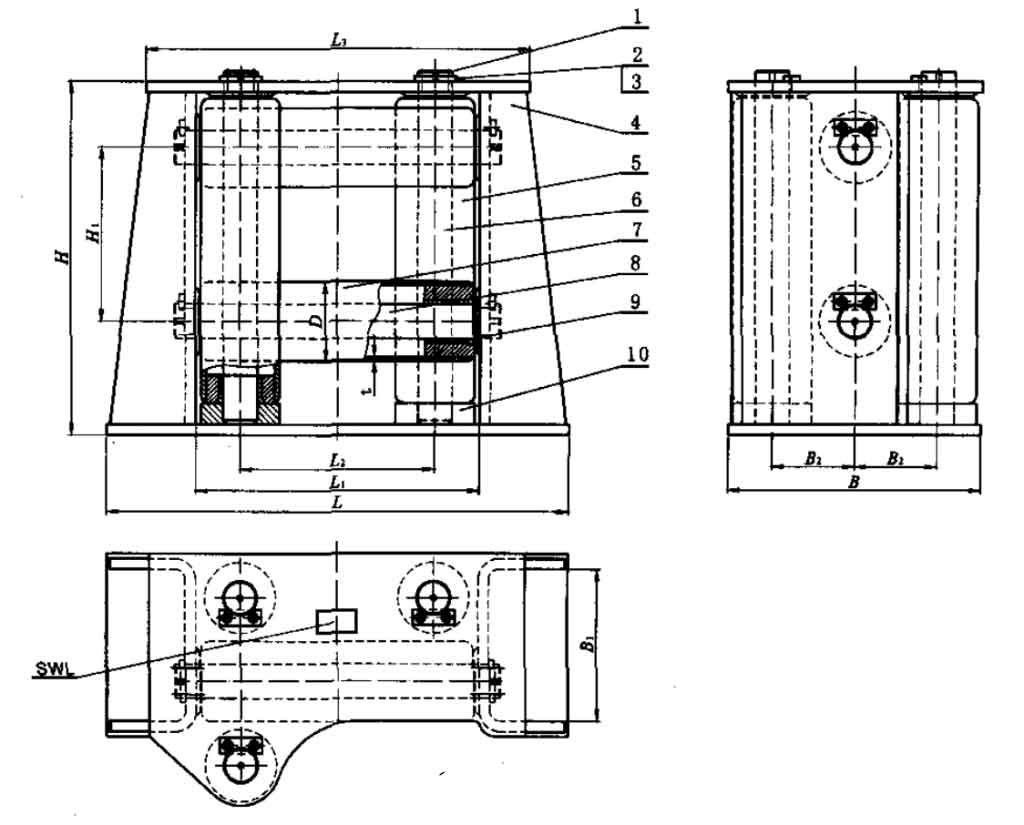

Type C

- Roller No.: 5 Rollers

- Weight: 139kg~2877kg

- Steel Cable Diameters: 14mm~44mm

- Nylon Rope Diameters: 36mm~100mm

| Nominal Dia.(mm) | Steel Cable Dia.(mm) | Nylon Dia.(mm) | SWL(kN) | B | B1 | B2 | D | H | H1 | L | L1 | L2 | L3 | t | Weight(kg) |

| 100 | 14 | 36 | 54 | 238 | 194 | 108 | 102 | 508 | 330 | 644 | 416 | 300 | 544 | 10 | 139 |

| 120 | 16 | 40 | 70 | 280 | 232 | 128 | 121 | 552 | 360 | 728 | 456 | 320 | 608 | 12 | 209 |

| 140 | 18 | 45 | 89 | 304 | 250 | 138 | 140 | 606 | 405 | 776 | 480 | 330 | 646 | 14 | 284 |

| 150 | 20 | 70 | 110 | 346 | 288 | 158 | 152 | 670 | 435 | 880 | 540 | 370 | 730 | 16 | 410 |

| 160 | 22 | 80 | 133 | 370 | 308 | 168 | 168 | 710 | 470 | 940 | 580 | 400 | 780 | 18 | 541 |

| 180 | 26 | 85 | 186 | 417 | 345 | 190 | 194 | 770 | 510 | 1030 | 620 | 420 | 850 | 20 | 723 |

| 200 | 28 | 95 | 216 | 459 | 385 | 210 | 219 | 820 | 550 | 1136 | 686 | 460 | 936 | 22 | 931 |

| 230 | 32 | 100 | 282 | 521 | 445 | 240 | 245 | 910 | 605 | 1256 | 746 | 490 | 1026 | 25 | 1253 |

| 260 | 36 | 100 | 357 | 590 | 500 | 270 | 273 | 1000 | 670 | 1430 | 850 | 560 | 1170 | 28 | 1852 |

| 320 | 44 | 100 | 533 | 714 | 620 | 330 | 325 | 1130 | 770 | 1690 | 990 | 640 | 1370 | 30 | 2877 |

Technical Requirements:

- The parallel degree of vertical roller and horizontal roller is less than L/500 ( L=the length of roller).

- The weight tolerance should not exceed 5%.

- All the steel parts shall be derusting. and the derusting grade shall be in accordance with the provisions of Sa2. Two anti-rust primer coatings must be after derusting. Paint should be uniform, with no hanging flow, wrinkle and other defects.

- The surface shall be smooth.