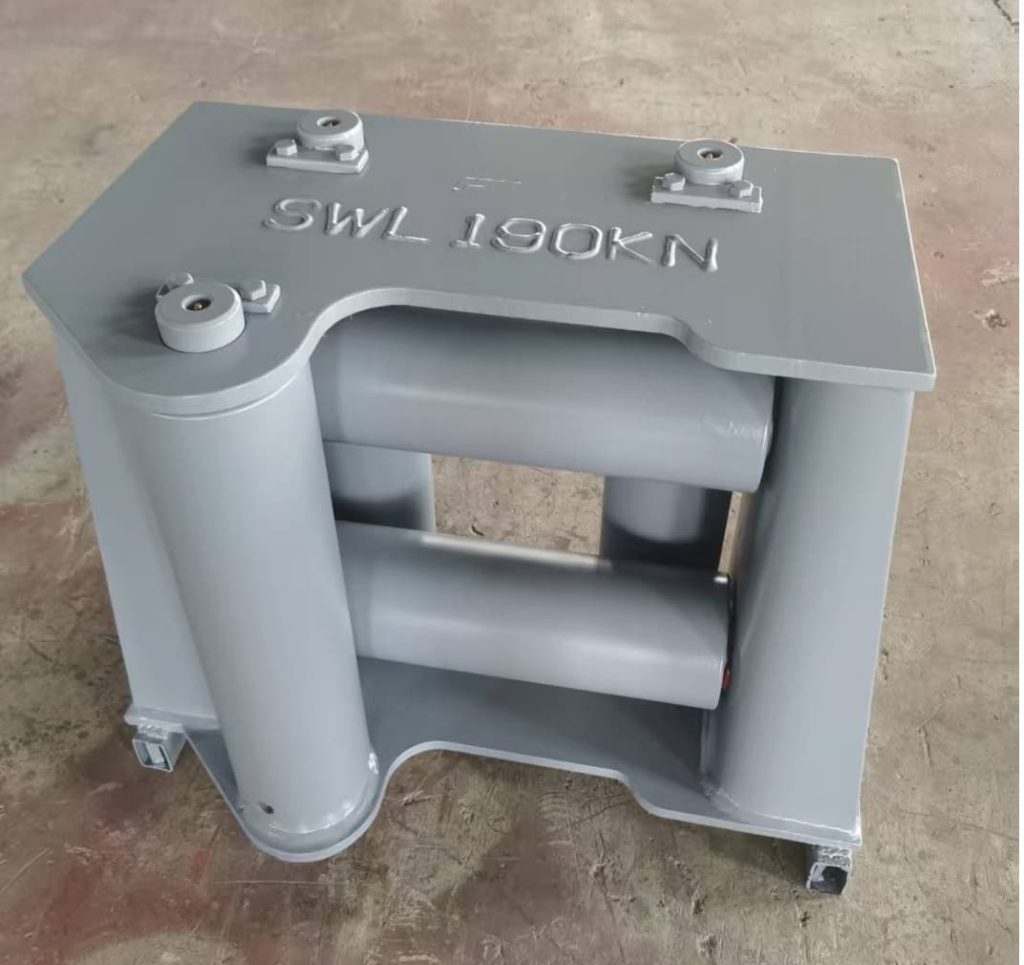

Universal roller fairlead is a common onboard fitting used for mooring and towing operations. It consists of vertical and horizontal rollers and can guide the cable from any direction. The universal roller fairlead we provide is a 4 roller fairlead, and the standard design has 2 vertical rollers and 2 horizontal rollers. It is made of high-quality steel with a diameter ranging from 100-320mm. The surface is treated with zinc-rich primer and anti-rust paint, which has a good anti-corrosion performance.

Horizontal roller fairlead, also known as universal roller fairlead, is a ship mooring device that can change the rope direction and fix the rope position. This type of roller fairlead is specially designed for a rope application and can be freely installed on the deck or welded into the bulwark. The abrasion of the mooring rope of the rollers fixed around the fairlead can be greatly reduced.

According to different production standards, marine fairleads are divided into CB*58-83 roller fairlead, JIS F 2014 roller fairleads, DIN81906 roller fairlead, CB*436-2000 single roller fairleads, DIN81907 roller fairlead, JIS F 2026 horizontal roller fairlead, CB*3062 horizontal roller fairlead, CB*3015 engineering ship mooring pipe and other types of fairleads. Boomarine can supply the appropriate roller fairleads according to various standards. We can also provide a range of customized solutions based on drawings. At the same time, we provide a series of different classification society certificates, such as CCS, ABS, LR, BV, DNV, NK, etc.

Features of Universal Roller Fairlead:

- Good wear resistance.

- Durable and long service life.

- The surface is coated with zinc-rich primer and anti-rust paint, which has good anti-corrosion performance.

- Smooth surface, can greatly reduce mooring rope wear.

Technical Requirements:

- Sharp edges to be removed.

- Fill chambers around the shaft with lithium-based grease before mounting the stern roller.

- Welding parts with no cracks, scars, holes, shrinkage, or alluvial soil such impact strength and appearance of the defects.

- All surfaces in contact with the rope must not have surface roughness or irregularities that could damage the rope due to wear and tear.

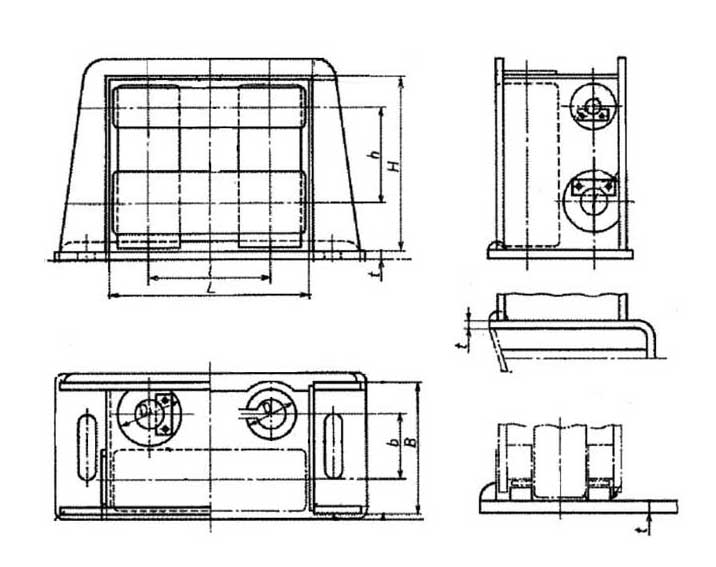

Parameters of Universal Roller Fairlead

| Diameter (mm) | Steel Rope Dia. | Nylon Rope Dia. | E | F | d | L | L1 | L2 | L3 | B | B1 | B2 | H | H1 |

Weight (kg) |

| 100 | 19.5 | 36 | 200 | 150 | 40-0.5 | 644 | 416 | 300 | 544 | 238 | 194 | 108 | 508 | 250 | 155 |

| 120 | 22.5 | 40 | 200 | 150 | 50-0.5 | 728 | 456 | 320 | 608 | 280 | 232 | 128 | 552 | 270 | 239 |

| 130 | 26 | 45 | 200 | 180 | 55-0.5 | 776 | 480 | 330 | 646 | 304 | 250 | 138 | 606 | 310 | 306 |

| 150 | 32 | 70 | 220 | 180 | 65-0.5 | 880 | 540 | 370 | 730 | 346 | 288 | 158 | 670 | 330 | 450 |

| 160 | 34.5 | 80 | 240 | 200 | 70-0.5 | 940 | 580 | 400 | 780 | 370 | 308 | 168 | 710 | 360 | 576 |

| 180 | 37.5 | 85 | 240 | 200 | 80-0.5 | 1030 | 620 | 420 | 850 | 417 | 345 | 190 | 770 | 380 | 756 |

| 200 | 43 | 95 | 260 | 210 | 90-0.5 | 1136 | 686 | 460 | 936 | 459 | 385 | 210 | 820 | 410 | 987 |

| 230 | 52 | 100 | 260 | 220 | 100-0.5 | 1256 | 746 | 490 | 1026 | 521 | 445 | 240 | 910 | 450 | 1370 |

| 260 | 60.5 | _ | 300 | 240 | 120-0.5 | 1430 | 850 | 560 | 1170 | 590 | 500 | 270 | 1000 | 500 | 2008 |

| 320 | 68 | _ | 320 | 250 | 150-0.5 | 1690 | 990 | 640 | 1370 | 714 | 620 | 330 | 1130 | 570 | 3352 |

Materials for Manufacturing Universal Roller Fairlead

- Frames and other plates: Weldable steel plates with yield points not less than 235 N/mm2, except for frames with rope guides of nominal sizes 400A, 400B and 400C, which shall be made of weldable steel plates with yield points not less than 315 N/mm2.

- Roller: Weldable steel plate with yield point not less than 235 N/mm2, except for rollers of nominal size 400A, 400B and 400C, which shall be made of weldable steel plate with yield point not less than 315 N/mm2, or equivalent material steel pipe.

- Axle: carbon steel with yield point not less than 345N/mm2.

- Bushing: Brass or bronze or the like.

Why Choose Us?

- All our products are manufactured in strict accordance with production standards.

- Strong design and production capacity.

- Strict inspections include incoming material inspection, flaw detection, etc., and double inspections must be carried out.

- High-quality pre-sales and after-sales service.

- Respond to any inquiry within 24 hours with the design or efficient solution of our engineers or technical support staff.

- Our company can provide standard and non-standard products to meet your various needs. We can customize products according to your drawings.

- Delivery on time, because we have a strict production plan and professional follow-up process.

- Best price and professional service.