The Panama chock is actually a mooring chock that complies with the “Panama Canal Rules“. For details, please refer to the National Standard GB 11586 or the Panama Canal Rules (ACP Rules).

Compared with other mooring chocks such as DIN standard chocks and closed chocks, the tensile strength and safe load of Panama chocks are slightly higher, and many ship owners even have to put the design calculations provided by the designer on board for reference.

A small Panama can define a type of chock, all because of the world-famous Panama Canal that connects the Pacific and Atlantic. If you want to cross this canal, you have to have a Panama chock. Why do you have to equip such standard chocks when crossing a canal?

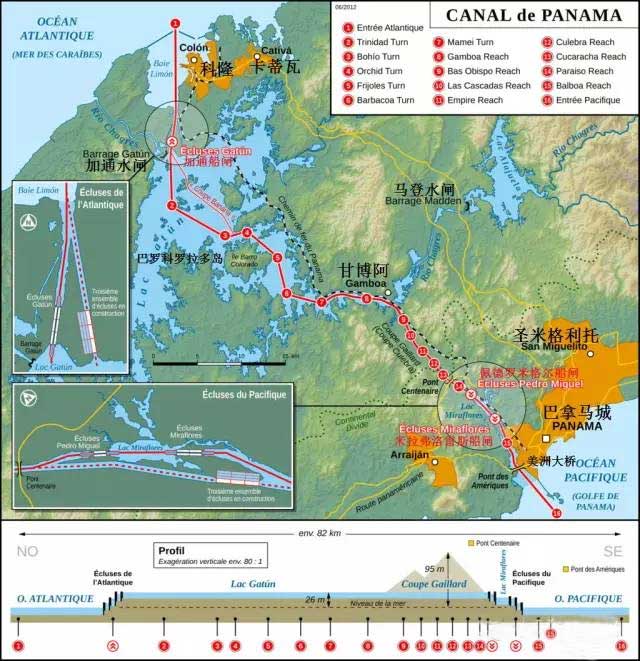

This has to start with the excavation of the Panama Canal. As you can see from the picture below, the Panama Canal was not dug from the Pacific coast to the Atlantic Ocean, because there was a large Gatun Lake in the middle, but actually only one artificial channel was dug at each end.

At that time, this design is also subjective and objective reasons. Objectively, because the Pacific side of the sea is much higher than the Atlantic side (5,6 meters at high tide), if dug into the Suez Canal as a straight-through canal, it will form a faster runoff from west to east, for the Caribbean side of the ship, the passage will be very difficult, and will take away all the fresh water in the middle of the lake, which is unbearable for a small country like Panama. So the French designers designed a method of setting up locks at both ends (three locks) and raising the water level in the middle (finally 26 meters), which greatly reduced the number of construction earthworks, and also greatly increased the reserve of freshwater lake, but the disadvantage is also obvious, that is, greatly reduced the efficiency of the passage. Not only do you have to cross the locks, but some sections also are one-way, and each time the locks are opened, a lot of fresh water is lost, so there is a limit to the number of openings. Because of this limitation, the Panama Canal’s toll is only a fraction of that of its brother, the Suez Canal.

After the opening of the canal, the number of ships passing through the canal increased gradually and their tonnage became larger because the voyage from the Pacific Ocean to the east coast of the United States was greatly reduced, and the maximum width of ships was set to fit the narrow artificial waterway of the Panama Canal, which was called “Panama type”. As shown in the picture, such a ship crossed the canal already close to both walls, and had to be towed by rail cars on both sides. It can be seen that the pulling wire rope and guide hole by the pulling force of the great, so the standard Panama Chock was born.