Table of Contents

Introduction of Mooring Ropes

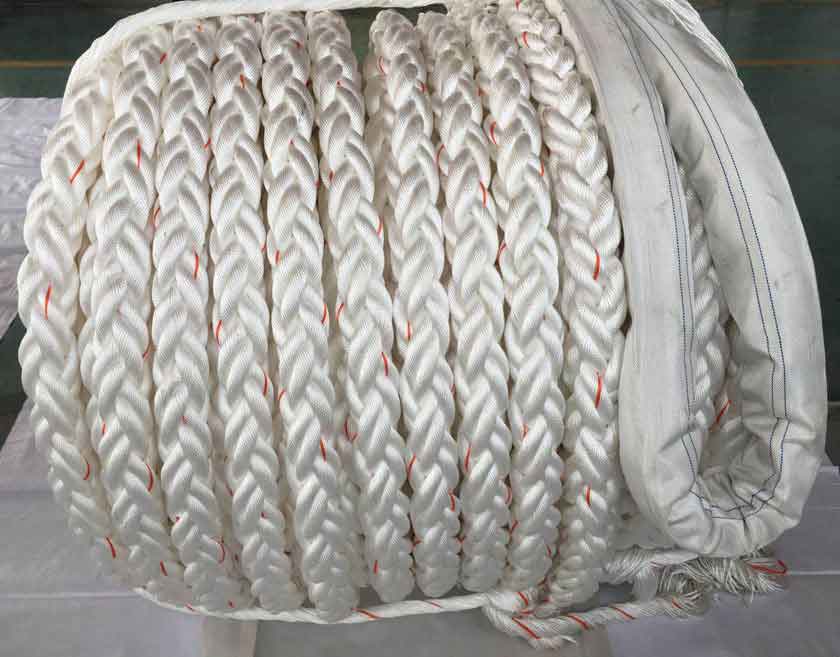

Mooring ropes, also known as dock lines or mooring lines, are ropes or lines used to secure a vessel to a dock or to another vessel.

Mooring ropes play a critical role in keeping a vessel safely secured to a dock or another vessel, preventing damage to both the vessel and its surroundings.

This essay will provide an overview of mooring ropes, including the types of ropes available, factors to consider when selecting ropes, maintenance techniques, tying techniques, safety considerations, and the importance of mooring ropes in marine operations.

Types of Mooring Ropes

Nylon Ropes: Nylon ropes are popular for their strength and elasticity, making them ideal for use in rough seas or heavy loads. They are resistant to abrasion, UV rays, and water absorption, but they tend to stretch over time and are prone to mildew if not dried properly.

Polyester Ropes: Polyester ropes are strong, durable, and resistant to abrasion, UV rays, and water absorption. They have less stretch than nylon ropes and are less prone to mildew, making them a popular choice for long-term mooring applications.

Polypropylene Ropes: Polypropylene ropes are lightweight and inexpensive, making them a popular choice for short-term mooring applications. They have low strength and elasticity and are prone to UV damage and water absorption, making them unsuitable for long-term use.

UHMWPE Ropes: UHMWPE rope, also known as Dyneema Rope, is produced with ultra-high molecular weight polyethylene fiber and high technology, it’s high strength, lightweight, and low elongation. Because it is woven, not twisted, it will not rotate when loaded.

Manila Ropes: Manila ropes are made from natural fibers and are known for their strength and durability. They are resistant to abrasion and UV rays but are prone to water absorption and mildew. They are less commonly used for mooring but are still a viable option in certain applications.

Factors to Consider When Selecting Mooring Ropes

- Strength: The strength of the mooring rope should be suitable for the weight and size of the vessel being secured. This is particularly important in areas with strong currents, high winds, or heavy vessel traffic.

- Abrasion Resistance: Mooring ropes should be resistant to abrasion to avoid damage from contact with sharp edges, rough surfaces, or other vessels. This is particularly important when mooring in areas with high traffic or heavy wave action.

- UV Resistance: Mooring ropes should be resistant to UV rays to prevent degradation from prolonged exposure to sunlight. This is particularly important when mooring in sunny or tropical climates.

- Water Absorption: Mooring ropes should have low water absorption to avoid rotting, mildew, or weakening of the rope over time. This is particularly important when mooring in areas with high humidity or frequent rain.

- Elasticity: Mooring ropes should have some degree of elasticity to absorb shock from wave action or sudden movements of the vessel. This is particularly important in areas with heavy wave action or wind gusts.

Maintenance of Mooring Ropes

- Inspection: Regular inspection of mooring ropes is essential to identify any signs of wear or damage. This includes checking for frayed or broken fibers, knots or twists in the rope, or signs of mold or mildew. Any damaged ropes should be replaced immediately.

- Cleaning: Mooring ropes should be cleaned regularly to remove salt, dirt, and other debris that can cause abrasion or weaken the fibers. Ropes can be cleaned with mild soap and water, and then hung to dry in a well-ventilated area. Avoid using harsh chemicals or high-pressure washers that can damage the fibers.

- Storage: Mooring ropes should be stored in a cool, dry, and well-ventilated area when not in use. Avoid storing ropes in direct sunlight or damp areas, as this can lead to rot or mildew. When storing, coil the rope neatly and avoid knots or twists that can cause weak spots in the fibers.

Techniques for Tying Mooring Ropes

- Cleat Hitch: The cleat hitch is a common method for securing mooring ropes to a dock or cleat. This involves wrapping the rope around the cleat and crossing the end of the rope over itself, then making a figure-eight with the rope around the cleat horns and finishing with a half hitch to secure the rope in place.

- Bowline Knot: The bowline knot is a versatile knot that can be used to create a loop at the end of a rope for tying to a cleat or other anchor point. This involves making a loop in the rope, then bringing the end of the rope up through the loop, around the standing part of the rope, and back down through the loop.

- Round Turn and Two-Half Hitches: The round turn and two-half hitches knot is a strong and secure method for tying a rope to a piling or other anchor point. This involves making a round turn around the anchor point, then making two half hitches around the standing part of the rope.

- Figure-Eight Knot: The figure-eight knot is a simple and reliable knot that can be used to create a stopper knot at the end of a rope or to join two ropes together. This involves making a loop in the rope, then bringing the end of the rope up through the loop, around the standing part of the rope, and back down through the loop to create a figure-eight shape.

Safety Considerations When Handling Mooring Ropes

- Personal Protective Equipment: It is important to wear appropriate personal protective equipment when handling mooring ropes. This includes gloves, safety glasses, and non-slip footwear to prevent injuries from slips, cuts, or burns.

- Proper Handling Techniques: Proper handling techniques are essential to prevent injuries when handling mooring ropes. This includes avoiding sudden movements or jerking of the rope, using proper lifting techniques, and avoiding overloading or overstretching the rope.

- Hazardous Weather Conditions: Hazardous weather conditions such as high winds, heavy rain, or lightning can create dangerous situations when handling mooring ropes. It is important to monitor weather conditions and avoid handling ropes in hazardous conditions.

- Emergency Procedures: In the event of an emergency such as a sudden storm or equipment failure, it is important to have emergency procedures in place for quickly releasing mooring ropes and securing the vessel. This may include having a designated person in charge of releasing the ropes, or having emergency release mechanisms installed on the mooring system.

Conclusion

Mooring ropes are essential components of marine operations that are used to secure vessels to docks, piers, or other anchor points. The different types of mooring ropes include nylon, polyester, polypropylene, UHMWPE and manila, each with its own strengths and weaknesses. When selecting mooring ropes, it is important to consider factors such as strength, abrasion resistance, UV resistance, water absorption, and elasticity. Proper maintenance of mooring ropes involves regular inspection, cleaning, and storage. Techniques for tying mooring ropes include the cleat hitch, bowline knot, round turn and two half hitches, and figure-eight knot. Safety considerations when handling mooring ropes include wearing personal protective equipment, using proper handling techniques, avoiding hazardous weather conditions, and having emergency procedures in place.

Mooring ropes play a critical role in ensuring the safety and stability of vessels in marine operations. Proper selection, maintenance, and handling of mooring ropes are essential to prevent accidents, injuries, and damage to vessels and equipment.