Many people do not know about bridge bearings, so what exactly is a bridge bearing? What role can they play? This article will introduce to you one by one.

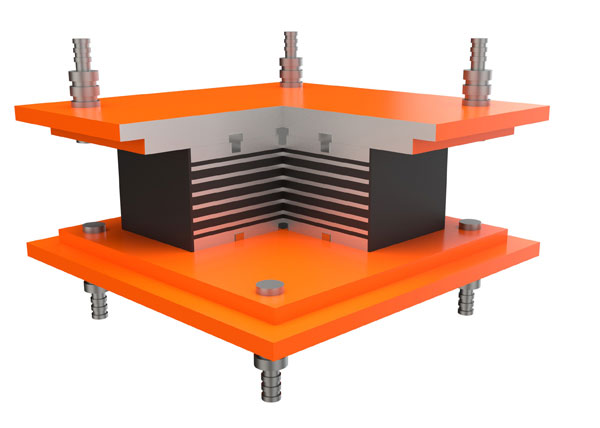

Bridge bearing is an important structural component to connect the bridge superstructure and substructure, located between the bridge and the mat stone. It is an important transmission device of the bridge, the design should be considered in addition to its adequate strength, stiffness and free rotation or movement performance, should also pay attention to facilitating maintenance and replacement.

Functions of Bridge Bearings

Function: Transferring various loads from the superstructure to the pier, and being able to adapt to the variable position (displacement and corner) generated by factors such as load, temperature change, concrete shrinkage, etc., so that the actual stresses of the upper and lower structure are in accordance with the designed calculation formula.

Arrangement of Bridge Bearings

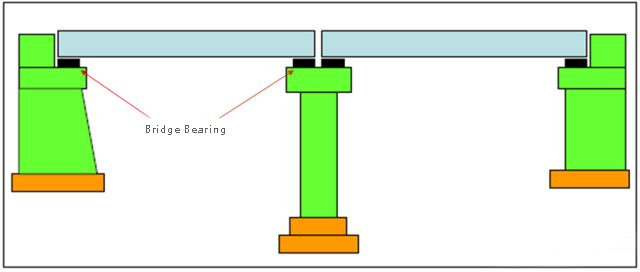

The bridge bearing is mainly set between the superstructure of the bridge and the pier. Its arrangement is mainly determined according to the structure type of the bridge and the width of the bridge.

One end of the simple-supported girder bridge has a fixed bearing, and the other end has a movable bearing.

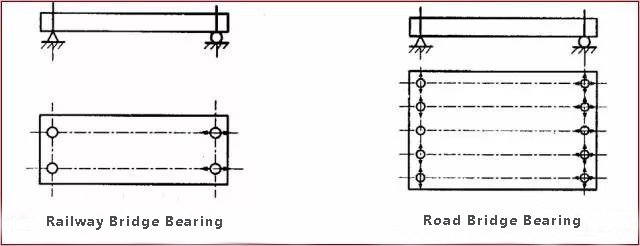

Railway bridge due to the bridge width is small, bearing transverse displacement is very small, generally only need to set a one-way (longitudinal) movable bearing.

Road girder bridge due to the wider bridge deck, to consider the possibility of bearing transverse bridge movement.

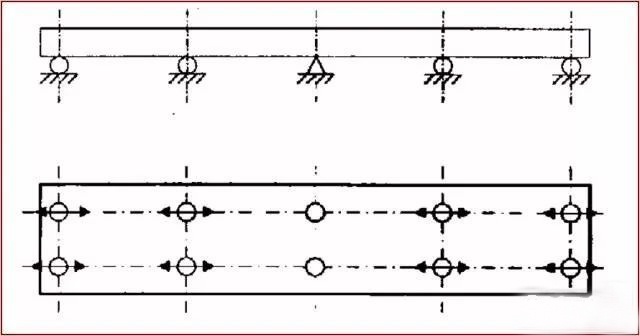

There is only one fixed support for each continuous girder bridge (composed of several spans between two expansion joints).

In order to avoid excessive expansion and contraction of the movable end of the beam, the fixed support should be arranged near the middle fulcrum of each length of the joint. However, if the pier body is relatively high, it should be avoided, or special measures should be taken to avoid excessive horizontal force on the top of the pier.

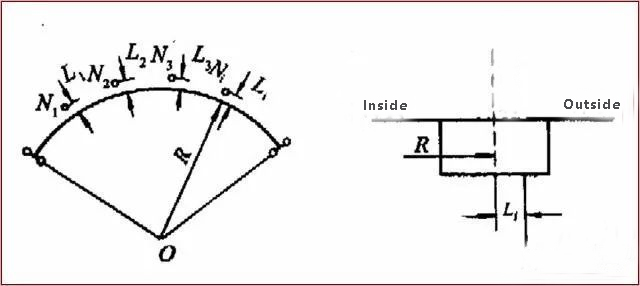

The bearing arrangement of curved continuous girder bridges will directly affect the internal force distribution of the girders, and at the same time, the bearings should be arranged in such a way that they can fully accommodate the possibility of free longitudinal and transverse rotation and movement of the curved girders.

A single pivot point bearing is permanently provided in the middle of the curved box girder, and a double bearing is provided at the end (or abutment) of the girder within one coupling only to carry the torque. The torque distribution of the curved beam can be adjusted by intentionally deviating the curved beam pivot point to the outside of the curve.

When the bridge is located on the ramp, the fixed bearing should be located at the lower end, so that the beam is pressed under the action of the vertical load along the ramp direction, so that it can offset part of the vertical load generated by the lower edge of the beam tension. When the bridge is located on a flat slope, the fixed bearing should be located at the front of the main traffic direction.

The use effect of the bridge, and the bearing can accurately play its function has a close relationship, so in the placement of the bearing, should make the bridge into the upper structure of the pivot point position and the lower structure of the bearing centerline alignment.

Replacement of Bridge Bearings

With the passage of operation time, various functions of the bearing and mat stone will deteriorate. In order to maintain the long-term stability of the bearing performance, it is necessary to reasonably replace them to ensure durability.

Bridge bearing replacement construction steps

1. Construction preparation

- According to the determined construction plan, do a good job in the construction of the construction site working platform. It is required to set up two brackets for each replacement set of supports, which is convenient for construction operators and monitoring personnel to use. The working platform should be firm and reliable to ensure the safety of personnel.

- Carry out the matching calibration of the jacks and oil pumps used. Two additional sets are added as spares.

- Select a new bearing of the same type as the original bearing, and do a good job in the test and inspection of the new bearing.

- Carefully clean up the sundries at the support and remove the redundant constraints near the support.

- The jack is installed in place.

- Arrange the stress and deflection observation points required for monitoring. Displacement observation points are set at the bridge piers to observe the displacement changes of the consolidation piers; two displacement observation points are set at the expansion joints of the bridge deck to observe the displacement changes at the expansion joints of the bridge deck.

- Organizational arrangement of construction personnel: The personnel entering the site are determined according to the needs of the project, including a project leader who is responsible for the unified arrangement and command of the project; a project technical leader who is responsible for the technical, task disclosure and Technical training; two experts, responsible for emergency treatment of temporary situations during the construction process, and several monitoring personnel.

2. Jacking construction

- If the bridge width is to be constructed should be temporarily closed before being jacked up to avoid construction accidents.

- After the preparation work is completed, the jack will be lifted under the unified command of the project leader. Control the jacking speed of the beam until all jacking is in place, and the support can be taken out smoothly. During the whole lifting process, the main girder, bridge deck and ancillary facilities must be carefully observed. If there is any abnormality, the lifting should be stopped immediately and adjusted, and then lifted again.

- After the jacking is in place, temporary support is required. The support should be firm and reliable, and the jack should not be loosened during the support process.

- After the support pad is taken out of the old support, before placing the new support, it is necessary to locate the original support to ensure the correct position after the support is replaced.

- Before installation, fill the silicone grease in the oil storage tank on the surface of the PTFE board in the PTFE board support to ensure that the surface of the PTFE board and the stainless steel surface are clean, and there should be no damage or scratching.

- When the bridge support is replaced and the main beam is in place, it should also be carried out in a distributed manner. First, the temporary support at the bottom of the beam is lifted, and then the beam body is dropped in place in sequence.

- Strictly control the jacking height of the beam body to avoid damage to the bridge deck and ancillary facilities caused by excessive jacking.

Construction precautions for bridge bearing replacement

Replacing bridge bearings is an important project. For most bridge bearings, the replacement methods are basically the same, but in the process of replacing bridge bearings, there are several details that cannot be ignored:

1. Lifting position

Different jacking methods should be adopted for different forms of bridges. For the section form composed of T beam or I-beam, generally, the backing plate can be placed under the beam body to be directly lifted with a jack; however, when jacking up hollow slabs and box beams, attention must be paid to the lifting position to avoid The bottom of the beam body is directly jacked up, and it is easy to select the two ribs and the web of the box girder to prevent damage to the beam body.

2. Jacking height

Strictly control the jacking height of the beam body to avoid damage to the bridge deck and ancillary facilities caused by excessive jacking.

3. Bearing pad stone

As we know, the bearing pad stone is to facilitate the future replacement of the bearing to leave the jacking jack position. However, in the process of operation, bearing pads are subjected to large forces, so it is easy to stress concentration and breakage phenomenon. In the process of bearing replacement, in order to ensure that the top surface elevation of the bridge bearing pad stone is consistent, it is necessary to repair it.

Summarize

With so many bridges in use around the world, and with more and more new bridges being built, the importance of bearings to bridges cannot be overstated. Through the investigation, at least 20% of the bridge bearings have serious diseases and need to be replaced and adjusted. Otherwise, the structural safety of the bridge itself will be affected. Through our export experience in recent years, we have the ability to provide you with tailor-made bridge bearing supply solutions, please feel free to contact us if you have any needs.