High damping rubber bearing, also called HDR, is one of the rubber bearing isolation, and its appearance is very similar to that of the lead rubber bearing. The rubber is made of high damping rubber material, with a layer of steel in the middle, and a lead-free plug, which can make the damping ratio up to 10% ~ 18%. It not only has all the properties of laminated bearing but also has good isolation performance, which can effectively reduce the damage caused by earthquakes to the bridge-building.

HDR high damping isolation rubber bearing according to the current implementation standard is JT 2009-26; It is applicable to all kinds of roads and municipal Bridges in the earthquake intensity area of 9 degrees and below.

Boomarine is a professional supplier of bridge bearings. In addition to the above features, we offer high damping rubber bearings that are environmentally friendly, easy to install and require no separation dampers. Depending on your requirements, the high damping rubber bearings can be made in rectangular or circular shapes. Customized sizes and designs are also welcome.

Features of High Damping Rubber Bearing:

- Excellent horizontal displacement. absorb shock energy effectively.

- The gravity load that can support the structure for a long time

- Excellent reset structure. there is no residual displacement.

- High initial horizontal stiffness to provide wind restraint

- High damping material. 10% to 18% damping capacity for shock absorption.

- Wide range structure for different environments and displacement requirements.

- Economical and high performance for a lower total construction budget.

- Easy installation and replacement for lower maintenance costs.

- Due to the newly developed natural rubber, the high damping rubber bearing has excellent creep performance.

- Temperature has little effect on the flexibility and damping performance of high-damping rubber bearings. Therefore, high-damping rubber bearings have a wide range of applications.

Applications of High Damping Rubber Bearing:

High damping rubber bearings are widely used in bridges, buildings and other earthquake-prone areas.

Working Principle of High Damping Rubber Bearing:

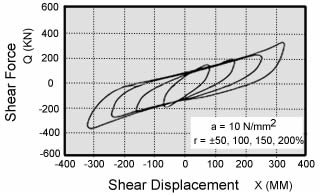

By improving the rubber formula and increasing the damping of rubber material, the damping ratio of high damping rubber bearing can reach 10%-18%. In the earthquake, the high damping rubber bearing produces large deformation and small stiffness, with excellent seismic effect. Because the elastic stiffness of high damping rubber bearing depends on its deformation degree. Deformation is small, the stiffness is large, and vice versa, deformation is large, the stiffness is small. And the use of this principle of high damping rubber bearing produces excellent seismic isolation function.

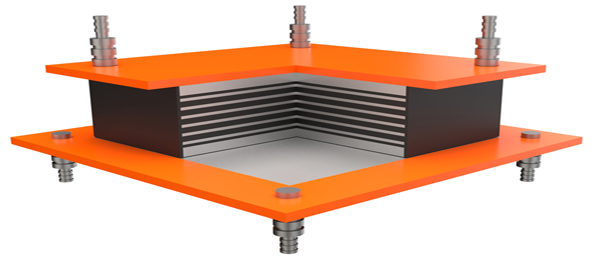

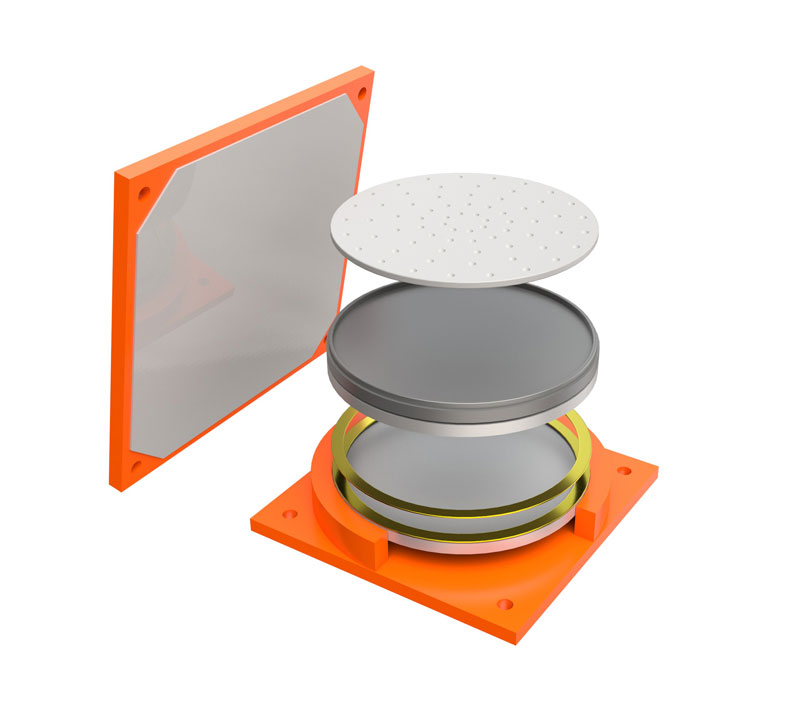

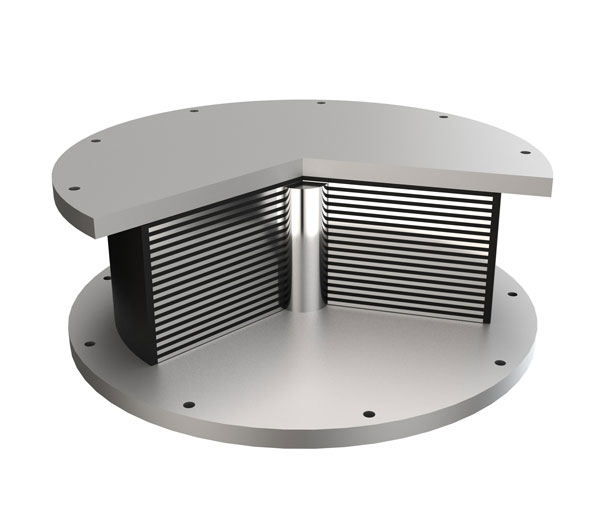

Types & Structures of High Damping Rubber Bearing:

- Working temperature range: -40 °C to +60 °C

- Rad: 0.006 rad and 0.008 rad

- Damping Ratio: 10% – 16%

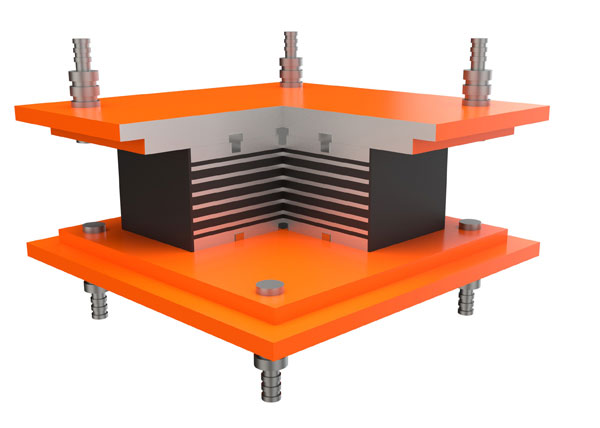

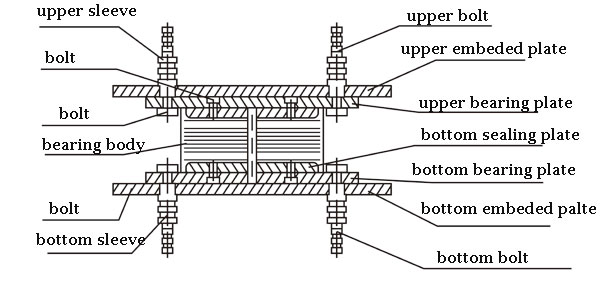

Type 1: The bearing, pier, and beam are to be connected with sleeve and bolt. The top and bottom of the bearing are embedded steel plates. The upper and lower bearing steel plate, and the sleeve are connected with bolts. The upper and lower embedded steel plate and the sleeve are welded together.

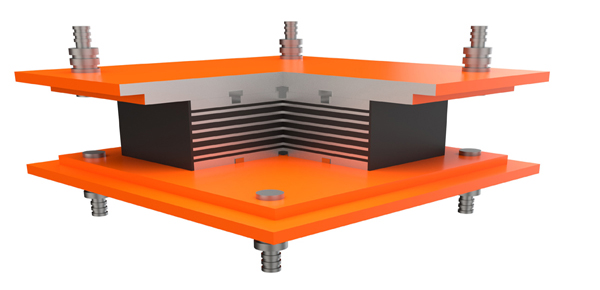

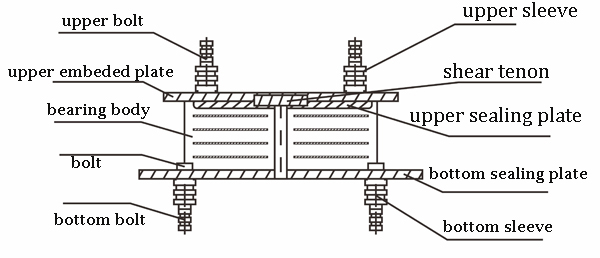

Type 2: The bearing, pier, and beam are connected by sleeve and bolt; the bottom of the bearing is not embedded steel plate, the bottom sealing plate and sleeve are connected by bolt, the upper embedded steel plate and the upper sealing plate are connected by shear tenon, the upper embedded steel plate and sleeve are welded together.

Product Photos: