The quality of marine rubber fenders has always restricted the use of production berths, troubled the safety of wharf and ship pilot berthing, and affected the scheduling of production ships. We should analyze and study the placement, type selection, use, and fabrication of fenders.

1. What Are The Production Quality Requirements For Rubber Fenders?

During the molding of rubber fender products, the cohesive force of the elastomer cannot be removed after being pressed with a large pressure, and there is an unstable trend during molding (the shrinkage rate of rubber depends on the type of rubber).

Therefore, when designing rubber products, both the formula and the mold should carefully calculate the mixing quality, otherwise, the product size may be unstable, thus reducing product quality problems.

When designing and producing rubber fenders, the rubber fender manufacturers shall consider the reaction force acting on the hull and the port berthing position, the deformation of rubber fenders after absorbing the ship’s kinetic energy, and the reaction force acting on the hull.

2. Which Marine Rubber Fender Material To Choose?

Filler Material

Generally, rubber fender enterprises use polyester cord fabric for filling, but the tensile and elastic properties of polyester are not as good as nylon, so nylon with high elastic properties is selected for a better fender.

External Material

Nylon is mainly used in two kinds of airbags and fenders, 126D2 and 126D3. These two kinds of cord fabrics are well made and have a very long service life.

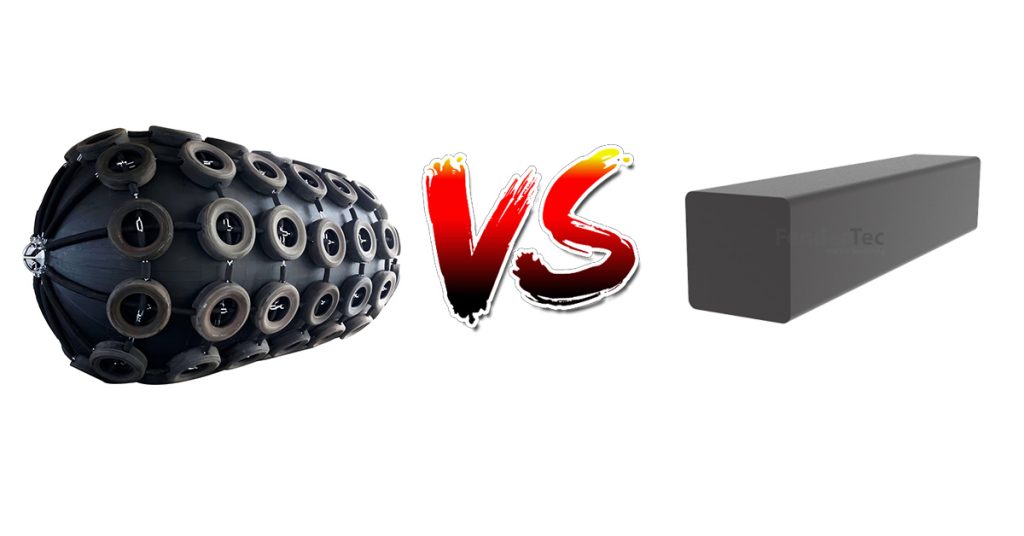

3. How To Select The Types of Marine Fenders?

Selecting types of marine fenders are mainly based on ship conditions, ship tonnage, water line speed, etc.

Arch V-Type Rubber Fender

At present, arched V-type rubber fenders are mostly used. Although fenders have been widely used and bridge piles are densely distributed, due to the small energy absorption of fenders, the surface is easy to be scratched and damaged, falling off and aging.

Rotary Rubber Fender

The rotary rubber fender uses a relatively large offset to solve the stress problem when the bridge pile is impacted. It is also a wise choice to use it in some narrow transport holes. However, due to the high engineering cost of the product, it is unlikely to be applied on a large scale.

Pneumatic Rubber Fender

As a key product of anti-collision, shock absorption, and energy absorption, pneumatic rubber fenders are simplified in model selection due to the emphasis on ports, which can achieve a good anti-collision effect and save costs. Except for tugs and small ships, large tonnage ships equipped with rubber fenders mainly use inflatable rubber fenders to protect ports and hulls when berthing.

4. How To Use Rubber Fender In Combination?

The combined use method of the rubber fender aims to overcome the shortcomings of the prior art and provide a rubber fender that can be used in combination.

Even if a single fender can not meet the needs of large ships, several fenders can be combined into a longer fender to meet the needs of a longer fender.

The rubber fender is a cylindrical ring, which is characterized by a plurality of projections on one end face of the rubber fender and a plurality of grooves on the other end face. The number of pins and slots is the same. The shape of the pin and groove is the same, both are cylindrical. The positions of the protrusions and grooves on the end face correspond to each other. The grooves and projections of two adjacent fenders can be used together.

5. How To Place Rubber Fender In Proper Position?

The spacing and elevation of marine rubber fenders are very important. It is necessary to ensure that the ship can not directly touch the quay wall under the most unlucky berthing sight point allowed by the standard. It is also necessary to ensure that the ship can safely berth at different tide levels and draughts, and has strong adaptability to ships of different tonnage. Fender is an energy-absorbing device for ship berthing stability. Due to the effect of wind, wave, and current, as well as the difference between wharf azimuth, and the influence of high and long period wavelet waves on the harbor basin, a large amount of energy can occur when a ship collides with a dolphin, which requires that the fender has a good energy absorption characteristics.

Summary

The rubber fender will affect the safety of the wharf and the ship’s pilot berthing, and affect the scheduling of production ships. This paper introduces the placement, selection, use, and manufacture of rubber fenders.