In modern port operations, the safe berthing of vessels is a key link to ensure the smooth operation of logistics transportation and the safety of port facilities. From offshore fishing vessels with a displacement of only a few dozen tons to giant LNG carriers carrying over 100,000 tons of liquefied natural gas, the impact forces generated by different types of vessels when berthing vary greatly. Rubber fenders, as key buffering devices for protecting ships and docks, need to meet diverse berthing requirements through technological iteration and precise adaptation. This article will systematically analyze the adaptation methods of rubber fenders from technical principles, engineering applications to special scenarios.

The Key Influencing Factors of Ship Berthing Impact

The essence of the berthing shock of a ship is the process of kinetic energy transfer, and its intensity mainly depends on three major types of factors:

Ship types and characteristics

The berthing characteristics of vessels range significantly from small fishing boats of a few tons to LNG carriers of hundreds of thousands of tons. Fishing boats usually have a small tonnage, a fast berthing speed (0.4-0.6m/s), and a high frequency (several times a day), but the impact energy is relatively low. Although large LNG carriers have a slow berthing speed (0.08-0.15m/s), the energy of a single impact can reach over 3,000 kJ, and they have special requirements for explosion prevention and fire protection. Bulk carriers and oil tankers lie between the two, but they have problems such as severe hull wear and oil corrosion.

Environmental dynamic factors

- Tidal range: A 7-meter tidal range in the Port of Liverpool, UK, causes a change in the impact Angle of up to 15°

- Wave period: Long-period waves (>10 seconds) will superimpose secondary shocks

- Water flow velocity: During the flood season in the Pearl River Estuary, the water flow velocity increases by 30% in terms of impact energy

- Wharf structure

- Fixed terminal: The rigid structure requires 90% of the energy to be absorbed by the fender

- Pile foundation wharf: Elastic deformation can share 40% of the impact force

- Floating berth: The moving phase difference can reduce the effective collision energy by 15%

The Core Technical System of Rubber Fenders

The essence of rubber fenders is indeed to achieve the conversion of kinetic energy to thermal energy through controllable deformation, and this process mainly relies on the viscoelasticity and high damping characteristics of rubber materials.

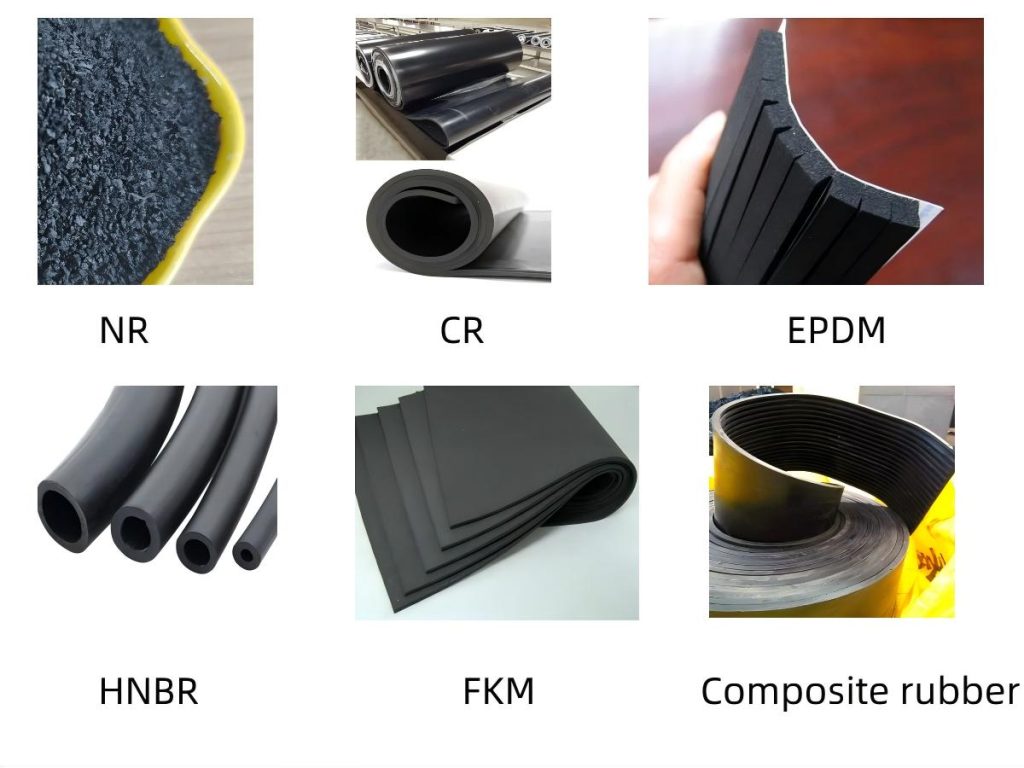

Materials technology

| Material type | Applicable Scenarios | Key Indicators |

| Natural rubber (NR) | Fishing boats and inland river vessels | The rebound rate is over 70% |

| Chloroprene rubber (CR) | LNG carriers and oil tankers | The oxygen index is >32% |

| Ethylene Propylene Diene Monomer (EPDM) | Chemical tanker | Acid and alkali resistance grade A |

| Hydrogenated nitrile butadiene (HNBR) | Polar ships | The elastic retention rate at -50℃ is 85% |

| Fluorine rubber (FKM) | Naval vessels | Salt spray resistance for 5000 hours |

| Composite rubber | Super-large vessel | Energy absorption >4000kJ/m³ |

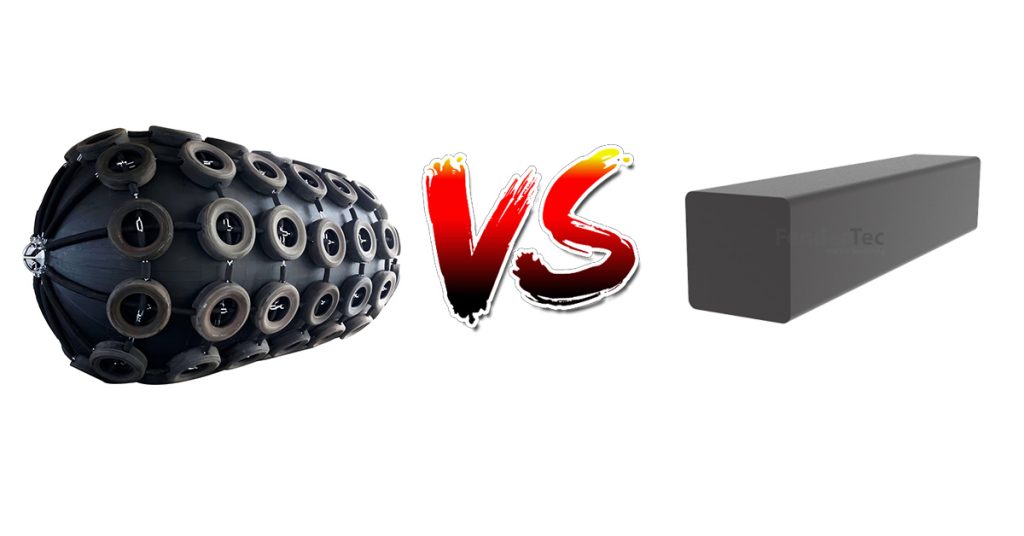

Structural design of marine fenders

The structural design needs to take into account both mechanical properties and installation adaptability.

- D-type/V-type fenders: commonly used in fishing boats, with a compact and multi-unit parallel design, and multiple fenders are arranged in parallel to disperse the impact force.

- Drum fenders: suitable for liquefied natural gas carriers, with a hollow structure that enables them to withstand large compression deformation.

- Floating fenders: maintain continuous contact with the hull through a heel-type design to reduce local stress concentration.

- Bionic design: In recent years, the concept of bionic design has been introduced into the fender structure. Innovative designs such as adsorption fenders that simulate octopus suction cups and honeycomb porous structures have significantly improved the energy absorption efficiency.

Industry Application Cases

1. Logical framework for case selection

The selection of typical cases follows the principle of “representativeness, technological innovation and significant benefits”. The case of upgrading fishing vessel ports focuses on cost optimization and performance improvement in medium and small load scenarios, while the LNG terminal project demonstrates technological breakthroughs in ultra-large load environments. The two form a complete application dimension coverage.

2. Upgrading of Fishing Vessel Ports (A Certain Fishing Port in Zhoushan, Zhejiang Province, China)

More than 200 fishing boats moor at this fishing port every day, and the average annual damage rate of the original traditional fender reaches 30%. By introducing honeycomb-shaped D-shaped rubber fenders made of modified natural rubber and combining them with elastic connection devices, the energy absorption efficiency of the fender has been increased by 40%, and its service life has been extended to more than 5 years. The intelligent monitoring system provides real-time feedback on the damage to the fender, reducing maintenance costs by 60% and effectively ensuring the efficient operation of the fishing port.

3. LNG Terminal Project (Expansion Project of North Field, Qatar)

In response to the berthing requirements of 267,000 cubic meter LNG carriers, the project adopts a customized floating drum-shaped fender system. Multi-point distributed layout, 6 main fenders +12 auxiliary units, with built-in pressure sensors and temperature monitoring devices. Through multi-body dynamics simulation to optimize the fender layout, the maximum contact stress was controlled within 8MPa, successfully addressing the berthing challenges under extreme sea conditions and providing a technical benchmark for the construction of global LNG terminals.

Special Scenario Solutions

Extreme environment classification

| Environment Type | Typical Areas | Core Challenges | Solutions |

| Low temperature polar regions | Arctic route | -50℃ embrittlement | HNBR material + steel frame |

| High temperature and high salt | Middle East ports | Accelerated aging | Nano clay modification |

| Highly corrosive | Chemical port | Media erosion | FKM rubber lining |

| Dynamic loads | FPSO | Fatigue fracture | Hydraulic-rubber composite |

Special vessels such as icebreakers/aircraft carriers

- When icebreakers operate in ice areas, their fenders need to withstand the combined load of ice mass compression and ship vibration. They adopt a composite structure of cold-resistant rubber and metal frames, which still maintains good elasticity in an environment of -40 ℃.

- As a super-large surface vessel, an aircraft carrier can have a berthing impact force that is more than ten times that of a conventional ship. Its dedicated fender integrates a hydraulic buffer device and an intelligent regulation system to achieve dynamic load adaptive control, ensuring the stability of the dock required for the safe takeoff and landing of carrier-based aircraft.

Conclusion: From “General” to “Precise Adaptation”

Modern fender technology has broken through the traditional model of “one specification applicable to all” and developed into an intelligent integration transformation. Statistics from the Japan Fender Association show that precise fitting solutions can extend the service life of fenders by 40-60% and reduce terminal maintenance costs by 25-35%. In the future, with the application of new technologies such as digital twins and artificial intelligence, rubber fender systems are expected to achieve intelligent management throughout their entire life cycle, opening a new chapter in the safety protection of port facilities.