Fenders serve pivotal functions as protective barriers absorbing shocks, distributing loads, and mitigating peak reaction forces. These functions serve to protect vessels and docking facilities, thereby minimizing disruption to operations and limiting potential damage to the facilities.

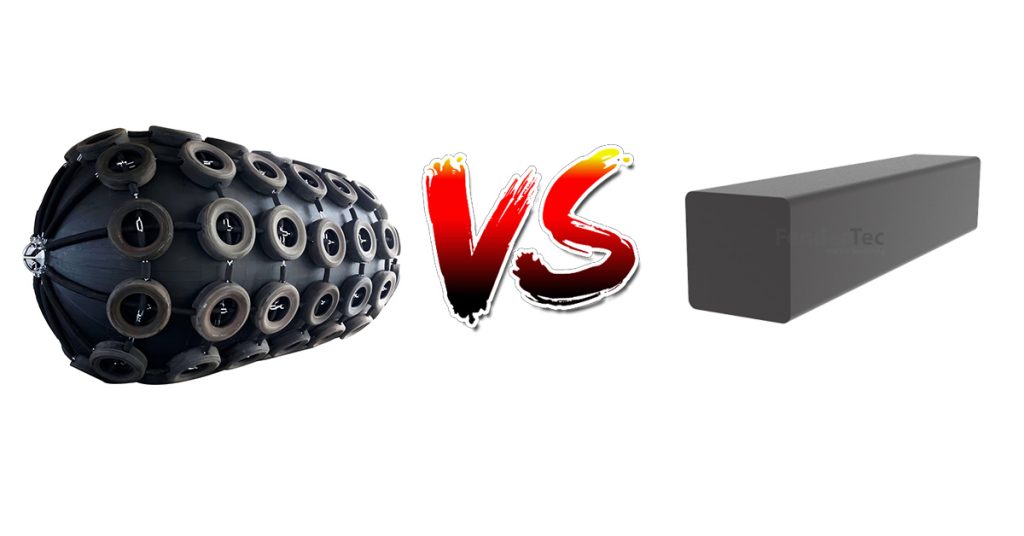

This review evaluates the performance of pneumatic and solid rubber fenders under various berthing scenarios. It seeks to clarify use cases, design considerations, and cost factors from which practitioners can derive practical guidance for more effective application.

Types of Rubber Fender

Here are the two common fender types you’ll find in ports:

Pneumatic fenders

Structure:

Rubber outer shell with internal fabric reinforcement and an air chamber; mounting often via flanges, chains, or brackets

Basic Principle:

Air compression absorbs impact energy, allowing large deformation with a relatively low reaction force; the soft outer layer spreads load over a bigger contact area

Typical Size Range:

Diameter roughly 0.5 m to 4 m+, length from 1 m to several meters (varies by use)

Solid Rubber Fenders

Structure:

One-piece molded rubber blocks with possible steel inserts or bolt holes for fixing to quays or dolphins

Basic Principle:

Rubber deforms under impact, converting kinetic energy into strain energy in the material;

Typical Size Range:

Thickness from ~50 mm to 1 m+; overall size depends on model (from small docks to heavy-duty berths)

Key Performance Differences

These two types of rubber fenders differ in performance characteristics as follows:

| Performance Feature | Pneumatic Fender | Solid Rubber Fender |

| Energy Absorption | Excellent; air compresses smoothly | Good, but less flexible |

| Compression Rate | High; softens impact effectively | Moderate |

| Rebound Force | Moderate; gentle bounce back | Higher; springs back more |

| Maximum Deformation | Large; cushions shock well | Moderate deformation |

| Speed Dependence | Works well across various speeds | Better for slower berthing |

| Suitable Ship & Docking | Large ocean vessels and variable waters | Small boats and stable docks |

| Durability & Lifespan | Requires regular air pressure checks | Tough and longer-lasting |

Choosing Fenders Based on Application

Choosing the right fenders for docking and activities on the water is not a one-size-fits-all operation. It needs to be adjusted to the particular application and surroundings. The following table gives different scenarios and suggested approaches for easy implementation.

Vessel Type

| Vessel Type | Notes | Fender Recommendation |

| Deep-water large vessels/Oil tankers/Container ships | Large draft, requiring high buffering stability and energy absorption with low peak reaction force | Prioritize pneumatic fenders; can pair with large solid rubber fenders as backup if berth is fixed |

| Coastal docks/Small boatyards/Inland river docks | High berth turnover, cost control is critical | Choose solid rubber fenders; add a small number of pneumatic fenders at key positions if needed |

Berthing Conditions

| Berthing Conditions | Notes | Fender Recommendation |

| Large tidal variations/Pronounced waves | Large relative displacement, requiring flexible buffering | Prioritize pneumatic fenders with proper air pressure and anti-abrasion measures |

| Strong currents/Streamlined flow | Dynamic pressure affects stability; anchoring is needed | Pneumatic fenders perform better; solid rubber fenders work for steady flow |

| Calm waters/Minimal relative motion | Low energy absorption demand, focusing on durability | Choose solid rubber fenders; add small pneumatic fenders if budget allows |

Wharf Structure Type

| Wharf Structure Type | Notes | Fender Recommendation |

| Concrete quays | Stable fixed points, easy anchoring | Choose solid rubber fenders; pair with pneumatic fenders for enhanced energy absorption if needed |

| Steel quays | Complex stress distribution, focusing on fixation | Choose solid rubber fenders with steel inserts; pneumatic fenders need anti-abrasion protection |

| Floating docks | Large relative motion, requiring flexibility | Prioritize pneumatic fenders; add small solid rubber fenders if necessary |

Maintenance and Cost Considerations

Pneumatic fenders

- “Stay airtight”. Overall condition must be checked once every 1–2 months: Measure the air pressure and note the change, adjusting if it’s off by ±5%. Look for outer rubber body cracks and wear. Inner fabric must be cleaned and valves checked every 3 months to mitigate air leaks.

- Repairs must be done by qualified personnel: Minor repair issues (small cracks and leaking valves) are resolved within 2–4 hours on-site, whereas major (broken fabric, chamber air leaks) require dismantling the rubber fender for 1–3 days to be repaired in the workshop, halting berthing work in the process.

- Neglecting rubber aging for 3–5 years means fender patching or full replacement, which will incur additional costs for removal and replacement. Dismantling the fender and chains for crane operation is expensive and time-consuming.

Solid rubber fenders

- Simple maintenance. There’s no need to check airtightness; however, superficial scratches or deformation must be assessed every 2–3 months. Anti-aging the surface and bolt tightening must be performed every 6 months.

- Simple repair. Superficial damage can be fixed in 1 hour (no special tools) using standard rubber adhesive and for full fender replacement, the time frame is half a day. Simply dismantle it by removing the old bolts, and the new one can be placed and bolted on.

- No big maintenance is required for 5-8 years and any surface part can be damaged without it greatly affecting the overall function.

Conclusion

Before buying fenders, think about the kind of vessel you will be using, the mooring conditions, and how much you’re willing to spend. To get the best combination of what you need, your budget, and what is safe and functional, it’s best to speak to a professional or the manufacturer.

FAQ

Q1: Are pneumatic fenders more prone to leaking air?

A: Yes, proper maintenance is key to preventing leaks and keeping performance up.

Q2: What advantages do pneumatic fenders have over solid rubber in rough seas?

A: Their design lets them flex more and absorb waves, tides, and shocks better.

Q3: How do I know when to replace my fender?

A: When you notice cracks, loss of shape, or unfixable air leaks, it’s time to replace them.