Marine Rubber Airbag is a Chinese independent intellectual property rights of innovative products, the products are mainly applied to ship launching and landing. Weightlifting and moving, installation of underwater buoyancy aids to salvage sunken vessels, etc. Airbags launching technology was developed based on the traditional slipway launching mode, overcoming the restrictions of traditional slipway launching mode. Marine rubber airbags are less limited by space, have no large mechanical equipment, can shorten the working period and save unnecessary costs. Today, Marine rubber airbags are widely used globally.

1. Airbag Structure and Material Requirements

1.1 Airbag Structure

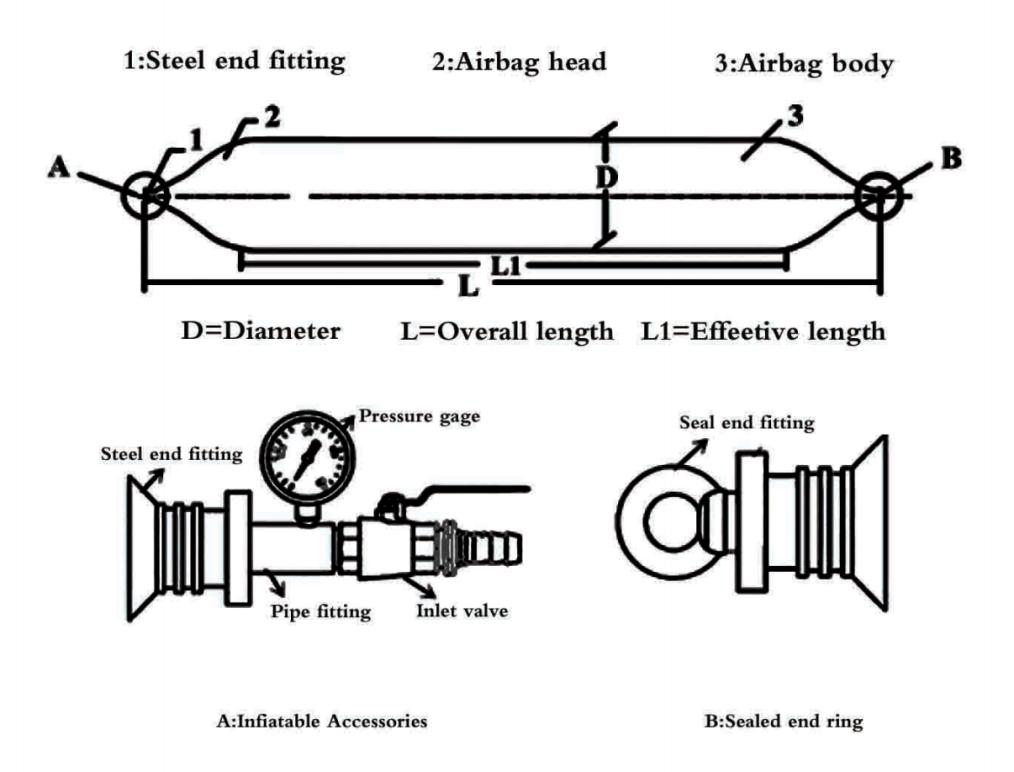

Marine Rubber Airbags’ structure consists of the outer rubber layer, synthetic cord reinforced rubber layers and inner rubber layer.

- Its shape characteristics: central body cylindrical + tapered on both ends.

- Cord layers: 4, 5, 6, 7, 8, 9, 10 layers

- Accessories: Pressure gauge, Inlet valve, Pipe fitting and seal end ring.

1.2 Material

Choose the best quality of imported natural rubber, such as smoked sheet rubber and 3L natural rubber from Thailand and Malaysia, which has good elasticity, ageing resistance, and will not take off the layer. Meanwhile, during the process of producing rubber, we use efficient stabilizers to make rubber more environmentally friendly and no cracks.

| No | Test item | Required value | Test method | |

| 1 | Tensile strength, MPa | ≥18 | ISO 37 | |

| 2 | Elongation at break, % | ≥400 | ISO 37 | |

| 3 | Hardness,°(Shore A) | 60±10 | ISO 7619-1 | |

| 4 | Tear Strength, N/cm | ≥400 | ISO 34-1 | |

| 5 | Compression set, %(70℃±1℃, 22h) | ≤30 | ISO 815-1 | |

| 6 | After thermal ageing at 70℃± 1℃, 96h | Holding of pull lengthening, % | ≥80 | ISO 188 |

| 7 | Holding of elongation at break, % | ≥80 | ISO 188 | |

| 8 | Change of hardness, °(Shore A) | ≤8 | ISO 7619-1 | |

| 9 | Static ozone aging test at 40℃x96h[ozone concentration (50 ±5) x 10-8 ], extension 20% | No crack | ISO 1431-1 | |

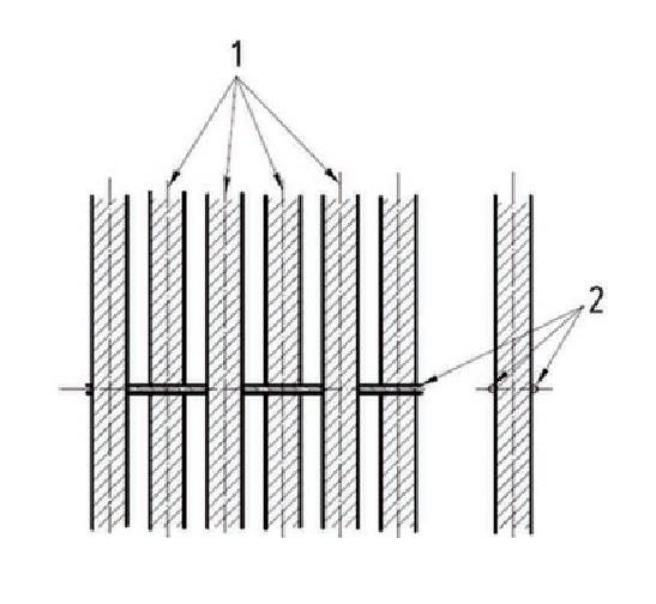

- Wrap threads that run vertically through the synthetic tyre-cord pattern.

- Weft threads that run perpendicular to the warp threads.

2. Size and Specification

Standard size of Marine Rubber Airbags:

- Diameter(D): 0.8m-2.0m

- Effective length(EL): 6.0m-18m

- Total Length(TL): 7m-20m

- Cord layers: 4, 5, 6, 7, 8, 9, 10, layers

| Diameter(m) | 1.0 | 1.2 | 1.5 | 1.8 | 2.0 | |

| Medium Pressure(4-5) | Test Pressure | 0.14-0.16 | 0.12-0.14 | 0.10-0.12 | 0.08-0.10 | 0.07-0.09 |

| Working Pressure | 0.12-0.14 | 0.10-0.12 | 0.08-0.10 | 0.07-0.09 | 0.06-0.08 | |

| High Pressure(6-8) | Test Pressure | 0.22-0.26 | 0.20-0.24 | 0.15-0.20 | 0.13-0.16 | 0.12-0.15 |

| Working Pressure | 0.20-0.24 | 0.17-0.22 | 0.13-0.18 | 0.11-0.14 | 0.10-0.13 | |

NOTE: Other sizes of airbags are also available, following the customer’s request.

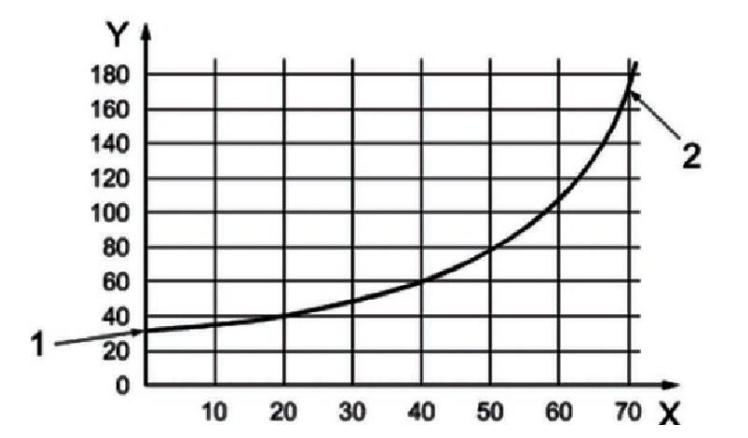

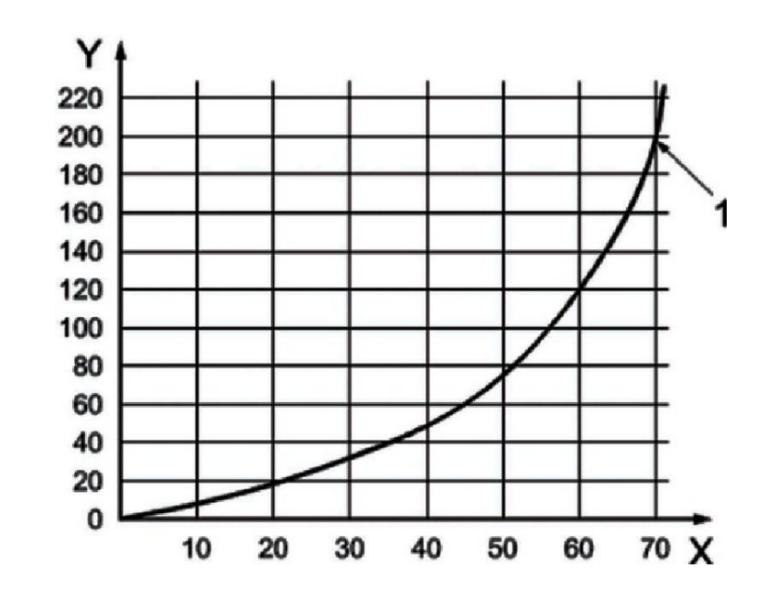

3. Performance Curves

3.1 Initial Internal Pressure:

Air pressure that fully inflates the airbag before compression. When the airbags are compressed by ship’s weight and its diameter will make a change. At the same time, the airbag’s internal pressure will increase with its compression rate.

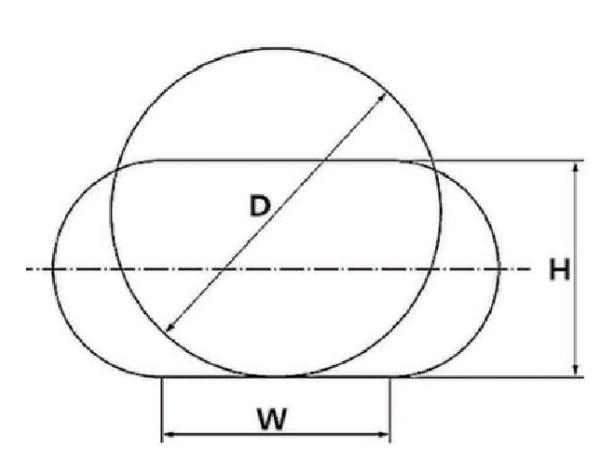

- P=(D-H)/D Where

- P=the percentage deformation(%)

- D=the original diameter of the airbag(m)

- H=the height of the compressed airbag(m)

3.2 Percentage deformation:

Ratio of the deformed height to the original diameter of the airbag while the airbag is being compressed.

The compression rate can be calculated using the formula:

- X=compress deformation

- Y=internal compress(kPa)

- 1=initial pressure

- 2=rated working pressure

- X=compress deformation(%)

- Y=bearing capacity per meter(KN/M)

- 1=bearing capacity

4. Reference for Select Airbag

The selection of airbags should be follow the vessel’s dimensions, type and launching weight.

Diameter:

The Airbag’s diameter should be considered the height of the docking blocks. In order to lift the ship’s safety, the airbag’s diameter must be higher than the docking blocks. Generally, the airbag’s diameter should be increased by 0.5m based on the block height. For example, if the docking block’s height is 1.0m, the airbag should be chosen with a Diameter not less than 1.5m.

Length:

The selection of the airbag’s length depends on the width of the vessels. The airbag’s effective length must be≥the width of the vessels. It will enhance the safety and steadiness of launching.

Airbag’s bearing capacity

The most important factor of ship launching, it must be consider the airbag’s bearing capacity. The airbag’s bearing capacity must be higher than the ship’s launching weight to guarantee launching process safety. So the number of layers will decide the airbag’s bearing capacity.

| 4-layer Intensive Airbag for ship launching and landing | ||||

| Diameter | Working Pressure | Working Height | Bearing Capacity per meter in length | |

| KN/m | Ton/m | |||

| D=1.0m | 0.13MPa | 0.6m | 81.72 | 8.33 |

| 0.5m | 102.12 | 10.41 | ||

| 0.4m | 122.53 | 12.49 | ||

| D=1.2m | 0.11MPa | 0.7m | 86.43 | 8.81 |

| 0.6m | 103.69 | 10.57 | ||

| 0.5m | 121.06 | 12.34 | ||

| 0.4m | 138.32 | 14.10 | ||

| D=1.5m | 0.09MPa | 0.9m | 84.86 | 8.65 |

| 0.8m | 98.98 | 10.09 | ||

| 0.7m | 113.21 | 11.54 | ||

| 0.6m | 127.33 | 12.98 | ||

| 0.5m | 141.46 | 14.42 | ||

| D=1.8m | 0.08MPa | 1.1m | 88.09 | 8.98 |

| 1.0m | 100.65 | 10.26 | ||

| 0.9m | 113.21 | 11.54 | ||

| 0.8m | 125.76 | 12.82 | ||

| 0.7m | 138.32 | 14.10 | ||

| 0.6m | 150.88 | 15.38 | ||

| D=2.0m | 0.07MPa | 1.2m | 88.09 | 8.98 |

| 1.1m | 99.08 | 10.10 | ||

| 1.0m | 110.07 | 11.22 | ||

| 0.9m | 121.06 | 12.34 | ||

| 0.8m | 132.04 | 13.46 | ||

| 0.7m | 143.03 | 14.58 | ||

| 0.6m | 154.02 | 15.70 | ||

| 5-layer Intensive Airbag for ship launching and landing | ||||

| Diameter | Working Pressure | Working Height | Bearing Capacity per meter in length | |

| N/m | Ton/m | |||

| D=1.0m | 0.17 MPa | 0.6m | 106.93 | 10.90 |

| 0.5m | 133.61 | 13.62 | ||

| 0.4m | 160.30 | 16.34 | ||

| D=1.2m | 0.14MPa | 0.7m | 110.07 | 11.22 |

| 0.6m | 132.04 | 13.46 | ||

| 0.5m | 154.02 | 15.70 | ||

| 0.4m | 175.99 | 17.94 | ||

| D=1.5m | 0.11MPa | 0.9m | 103.79 | 10.58 |

| 0.8m | 121.06 | 12.34 | ||

| 0.7m | 138.32 | 14.10 | ||

| 0.6m | 155.59 | 15.86 | ||

| 0.5m | 172.85 | 17.62 | ||

| D=1.8m | 0.09MPa | 1.1m | 99.08 | 10.10 |

| 1.0m | 113.21 | 11.54 | ||

| 0.9m | 127.33 | 12.98 | ||

| 0.8m | 141.46 | 14.42 | ||

| 0.7m | 155.59 | 15.86 | ||

| 0.6m | 169.71 | 17.30 | ||

| D=2.0m | 0.08MPa | 1.2m | 100.65 | 10.26 |

| 1.1m | 113.21 | 11.54 | ||

| 1.0m | 125.76 | 12.82 | ||

| 0.9m | 138.32 | 14.10 | ||

| 0.8m | 150.88 | 15.38 | ||

| 0.7m | 163.43 | 16.66 | ||

| 0.6m | 175.99 | 17.94 | ||

| 6-layer Intensive Airbag for ship launching and landing | ||||

| Diameter | Working Pressure | Working Height | Bearing Capacity per meter in length | |

| N/m | Ton/m | |||

| D=1.0m | 0.20MPa | 0.6m | 125.76 | 12.82 |

| 0.5m | 157.16 | 16.02 | ||

| 0.4m | 188.65 | 19.23 | ||

| D=1.2m | 0.17MPa | 0.7m | 133.61 | 13.62 |

| 0.6m | 160.30 | 16.34 | ||

| 0.5m | 187.08 | 19.07 | ||

| 0.4m | 213.76 | 21.79 | ||

| D=1.5m | 0.13MPa | 0.9m | 122.63 | 12.50 |

| 0.8m | 143.03 | 14.58 | ||

| 0.7m | 163.43 | 16.66 | ||

| 0.6m | 183.94 | 18.75 | ||

| 0.5m | 204.34 | 20.83 | ||

| D=1.8m | 0.11MPa | 1.1m | 120.96 | 12.33 |

| 1.0m | 138.22 | 14.09 | ||

| 0.9m | 155.59 | 15.86 | ||

| 0.8m | 172.85 | 17.62 | ||

| 0.7m | 190.22 | 19.39 | ||

| 0.6m | 207.48 | 21.15 | ||

| D=2.0m | 0.10MPa | 1.2m | 125.76 | 12.82 |

| 1.1m | 141.46 | 14.42 | ||

| 1.0m | 157.16 | 16.02 | ||

| 0.9m | 172.85 | 17.62 | ||

| 0.8m | 188.64 | 19.23 | ||

| 0.7m | 204.34 | 20.83 | ||

| 0.6m | 220.04 | 22.43 | ||

5. Applications & Operation

Ship Launching Process:

1) All obstacles shall be cleared along the way of the airbags, including the ship bottom.

2) The bow of the ship shall be tied to the windlass with mooring steel wire ropes. One end of the steel wire rope shall be tied to the strength member of the ship, such as a bollard or a special horn, the other end shall be tied to the pulley set of the towing system.

3) Airbags shall be placed underneath the ship.

4) The airbags are to be filled from the stern to the bow. Initially, the airbags are not to be fully inflated. Having inflated all airbags and ensured that they made contact with the ship’s bottom, the airbags shall be filled to the specified pressure (0.10MPa-0.11MPa).

5) When the ship’s bottom is lifted higher than the docking blocks and the airbags are bearing the weight of the ship, the docking blocks shall be removed. After all the docking blocks are removed, adjust the internal pressure of the airbags to balance the force.

6 After the workers and other personnel who are going to stay onboard during the launching have boarded the ship, remove the ladders and gangways and so on.

7) All the airbags should be centered on the ship and upright for the launching operation.

8) Start the towing winch to release the ship slowly. When the first airbag leaves the bow, move it to the stern and place it at the planned position. Repeat the former process until moving ship to the sea shore.

9) Depending on the conditions of the slipway and the water area, one of the following launching methods may be used:

- If the area of water is wide enough, one can launch the ship by moving the ship to the water’s edge, disengaging the windlass, removing or cutting the tow line and letting the ship slide into the water by itself.

- If the area of water is not wide enough, use the windlass to control the launching speed and let the ship glide into the water slowly.

- If the stern of the ship is built directly over the water and no windlass is available, the ship shall be secured to the ground anchor by the rope before filling the airbags. The minimum water depth needed for launching is to be calculated. The ship may be launched by herself into the water by cutting off the rope or letting off the ground anchor when there is enough water depth.

10) If the ship is very large, it is necessary to install the slip stopper.

11) After use, all airbags shall be reclaimed.

Ship Landing Process:

1) The ship should be fastened with a guy rope or cable attached firmly to the winch.

2) After the ship is fastened with a winch, choose a reasonable position near the bottom of the bow to insert one or more airbags, which act as the fulcrum for the winch to move the ship when inflated and lift the bow. If it is difficult to insert airbags at the bottom of the bow, we can also insert airbags from one side to another side. However, for a heavy ship, the quantity of bow lifting airbags should be increased until they can lift the bow. For a V-shaped bow ship, the bow lifting airbags should be inserted at the position where they can have a bigger contact area with the bottom of the ship. Besides that, we can also place the airbags at the appropriate positions at low tide and pull the ship upon the airbags at high tide, then inflate the airbags to lift the ship. In one word, the ship landing process should depend on the actual situation.

3) When the ship’s bow is lifted, people should start the winch to pull the ship towards land and insert more airbags into the space between ship’s bottom and the land until the full ship is pulled onto the slipway.

4) Adjust the airbags’ pressure to lift the ship’s bottom higher, then insert the docking blocks and withdraw the airbags.

5) After use, the airbags should be cleaned up and dried in the sun, then they should be coated with talcum powder to be stored in a dry place.

More Applications:

Marine rubber airbags are used for heavy lifting and moving

Due to marine rubber airbags having a strong bearing capacity, sometimes they can also be used for heaving lifting and moving.

Salvage Rubber Airbags (Salvage Pontoon)for salvage sunken vessels

Salvage Rubber Airbag is made of rubber material, which is different from the metal material of other salvage equipment. It can produce water buoyancy, the overall sealed, submerged in water can bring huge buoyancy. So it is mainly used for salvaging sunken Vessels, floating docks and some other emergency rescue projects, etc.

Specifications:

| Diameter Length | Buoyancy(tons) | ||||

| 1.0m | 1.2m | 1.5m | 1.8m | 2.0m | |

| 5m | 3.93 | 5.65 | 8.84 | 12.72 | 15.71 |

| 6m | 4.71 | 6.79 | 10.60 | 15.27 | 18.85 |

| 7m | 5.50 | 7.92 | 12.37 | 17.81 | 21.99 |

| 8m | 6.28 | 9.05 | 14.14 | 20.36 | 25.13 |

| 9m | 7.07 | 10.18 | 15.90 | 22.90 | 28.27 |

| 10m | 7.85 | 11.31 | 17.67 | 25.45 | 31.42 |

| 11m | 8.64 | 12.44 | 19.44 | 27.99 | 34.56 |

| 12m | 9.42 | 13.57 | 21.21 | 30.54 | 37.70 |

| 13m | 10.21 | 14.70 | 22.97 | 33.08 | 40.84 |

| 14 m | 11.00 | 15.83 | 24.74 | 35.63 | 43.98 |

| 15m | 11.78 | 16.96 | 26.51 | 38.17 | 47.12 |

| 16m | 12.57 | 18.10 | 28.27 | 40.72 | 50.27 |

| 17m | 13.35 | 19.23 | 30.04 | 43.26 | 53.41 |

| 18m | 14.14 | 20.36 | 31.81 | 45.80 | 56.55 |

7. Maintenance & Repair, How to repair an airbag?

Step 1: Clean the surface of airbags

When you ready to repair airbags,you must clean up the airbag’s surface to make sure there is no sand or oil on it. Then dry it and put a clean place. Please make sure that do not immersed airbags into the water more than 10 minutes before repair.

Step 2: Check and mark the damage area

Mark the repair area of airbags, which must be expand from center to outside(20-26cm) and remember that do not ignore the hiding damage areas.

Note: the expansive range depends on the size of damage areas.

Step 3: Repair

- Wear the surface of the damaged area until the cord is exposed and pay attention not to damage cord layer.

- For some long cracks, it needs to use a needle and a cord layer to suture, sewing needle position about 2-3cm away from crack, about 10 cm distance between stitches.

- Wash the surface of the repair part with gasoline and dry it.

- Brush up some special glue on the repair part, which made by mixing raw rubber material with a gasoline mixture. The ratio of raw rubber material to gasoline is 1:8, then dry it again.

- Prepare the repair rubber material and the repair material should be same with the airbags. Meanwhile, the structure layer 2-6 will be based on the size of the damage area. Seal the leakage area using pure rubber belt of 1mm thickness, the belt width and length should be more than 1cm around the crack.

- Put the layers on the damaged areas. The first layer of interleave is ordinate, the second layer of interleave is bias. The angle should be the same as the airbag, and it should be 20mm bigger than the first layer. The third layer is also bias, the angle should be contrary to the second layer. It also needs 20mm bigger than the second layer. From 4-layer to 6-layer is keep the same steps. Circular angle should be required by interleave and the semi-diameter should be 40-50mm.

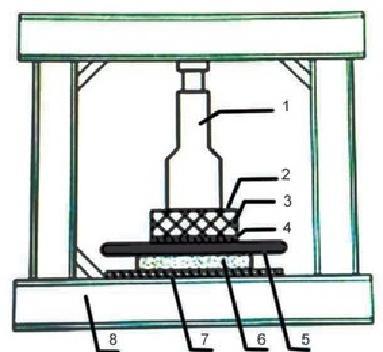

Step 4: Thermal vulcanization Process

Using a simple working structure to vulcanize the damaged areas.

During the process of vulcanization, please remember to control the temperature up to 150±5 °C and push pressure using a jack. Then close the heat steel plate and permit it to cool very slowly to 60(about 40 minutes). During this time, don’t remove the jack.

Step 5: Inspection

Check the repair area to make sure that no leakage in it. Finally,inflate it and make a pressure test.

Repair Process

- Jack

- Plancon

- Heating plate

- Cotton cloth

- Airbag

- Sandbag

- Steel plate

- Steel structure

8. Packaging and Shipment

Packaging:

All of the airbags can be folded and then bundled up

Shipment:

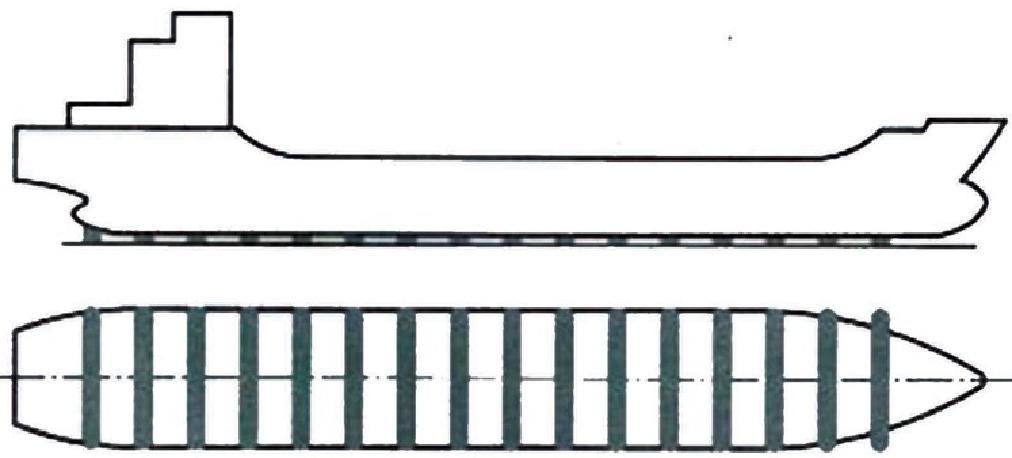

9. The arrangements of airbags

Launching type

Based on the ship shapes,the ship may be launched,using airbags,by either end launching type (see A.2) or side launching type (see A.3).

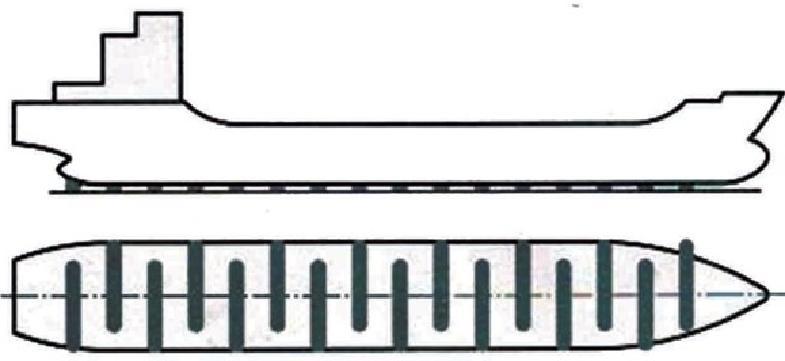

End launching type

There are three ways to arrange airbags when using the end-launching type.

They are:

(1) linear arrangement (see Figure A.1)

(2) Staggered arrangement(see Figure A.2)

(3) Two-line arrangement (see Figure A.3).

As for which arrangement to use, it will depend on the ship’s width and the length of the airbags.

- When the ship’s width is not greater than the effective length of the airbags, the linear arrangement shall be selected.

- When the ship’s width is greater than the effective length of an air bag and less than the effective length of two airbags, the staggered arrangement shall be selected.

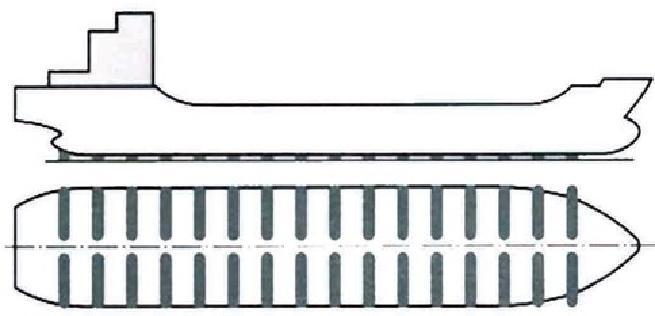

- When the ship’s width is greater than the combined effective length of two airbags, or for a special ship such as a catamaran HSC or split hopper barge, the two-line arrangement shall be selected. The distance between the near ends of two airbags is greater than 0.2m.

Figure A.1-Linear arrangement

Figure A.2-Staggered arrangement

Figure A.3-Two-line arrangement

Side Launching Type

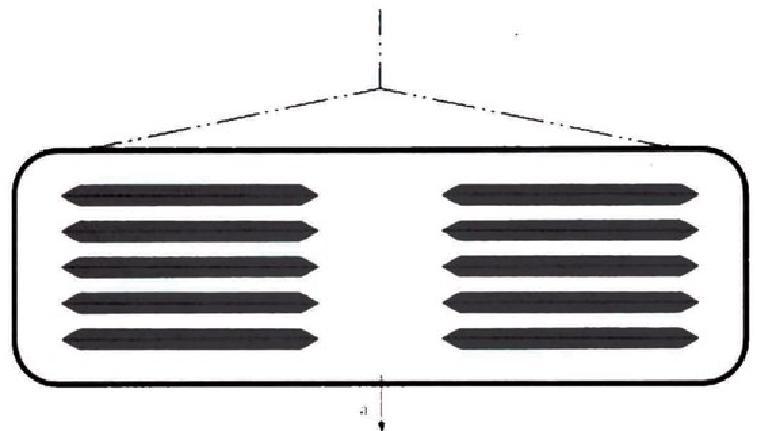

For small flat-bottom ships, the side launching method may be utilized (see Figure A.4). In this case, the airbags of the same specification, the same diameter, and the same length shall be used.

Figure A.4-Side launching

The airbags shall be divided into two groups, and be evenly arranged under the bow and the stern ends of the ship. The distance between the two airbags shall be made equal. The distance between the ends of two groups shall be greater than 1m but not greater than 10 percent of the ship’s length.

The hauling rope shall be fixed at the middle of the two airbag groups and be perpendicular to the hull of the ship.

10. Notes of Marine Rubber Airbags

Over Pressure Control

Strictly control the inner pressure of airbags not exceed the safety working pressure.

Avoid Sharp Objects

The contact surface of airbags must not have sharp, prominent hard objects to prevent puncturing the airbags. So when ship launching and landing, it must clean up the slipway and must not have sharp, hard objects.

Prevent Twisting

Avoid the lengthwise twist of airbags during airbag for ship launching and landing.

Avoid Shock Loading

After filling airbag should try to avoid shock loading, especially in the fall of ship docking blocks, when hoisting airbags has lift most of the hull, when removing blocks and fill in the airbags in the process, if the remaining one, two block was only pressured, at this time do not use artificial to remove the docking blocks, because once the block off hull gravity drop impact is likely to make the airbag burst.

The right approach: should adjust the hoisting airbags’ pressure until the ship’s bottom is lifted higher than the docking blocks, and then remove the blocks. And as in the process of moving ship collision with other objects, sometimes it can cause airbag breakage.

Storage:

When the airbags are not to be used for a long period of time, they should be drained, cleaned, dried, filled with talc powder, and the exterior surfaces should be coated with talc powder. The airbags should be maintained in a dry, ventilated room and be protected from light. The airbags should be stored in a relaxed condition free from tension, compression or other deformation.

The airbags should be kept away from any heat source.

The airbags should be protected from acids, alkalis, oils or organic solvents.