The most financially impactful challenges in everyday port operations are rubber fender failures. Large container ships and cargo carriers dock and deliver heavy impacts to shorelines—and to rubber fenders, port safety fenders, withstand these impacts every day. Due to heavy and non-stop usage, most rubber fenders must be replaced after an exhausting one-year service. This leads to a series of operational downtimes and costs his/her customer considerable amounts of money.

The innovative rubber fenders with UHMWPE facings have started to make a difference in the industry. From small fishing ports to major international container terminals, there has been an industry-wide acceptance of these products. UHMWPE is not an ordinary value-added fender liner; it improves operational fender durability and helps port operators run their operations more efficiently.

What Is UHMWPE?

Ultra-high molecular weight polyethylene (UHMWPE) is a specialized industrial plastic designed to withstand the extreme conditions present at the Port while also having a molecular weight that vastly exceeds the average polyethylene. This means it significantly outperforms regular flimsy plastics, as well as corrodible steel.

In summary, UHMWPE possesses all the required functionalities needed to fulfill the role of a rubber fender at ports. It has low friction, withstands impacts of all magnitudes without harm, and has complete corrosion resistance to seawater, salt spray, and durable chemicals. It also is lightweight, allowing it to be installed quickly and easily without the use of heavy equipment or specialized teams. It isn’t just an upgrade: it completely reimagines what a rubber fender is capable of, allowing high-maintenance components to become reliable, durable assets.

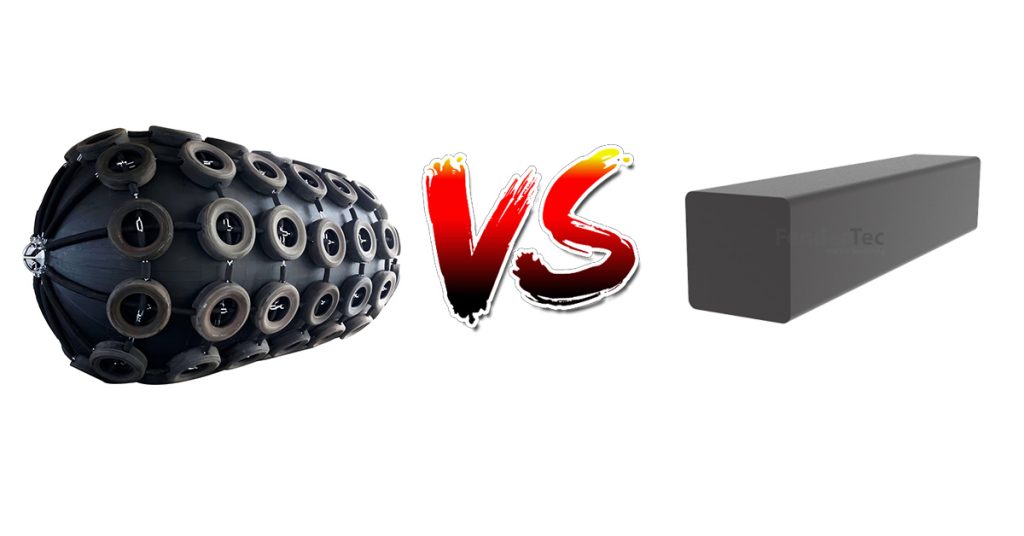

UHMWPE vs. Traditional Rubber Fender Liners

Now that you know what UHMWPE is, let’s see how it stacks up against the materials ports have relied on for decades:

| Material | Wear Resistance | Maintenance Needs | Service Life | 5-Year Total Cost | Key Drawback |

| UHMWPE Facings | Exceptional | Minimal (1x/3–5y) | 3–5+ years | Low | None—outperforms in all areas |

| Steel Plates | Poor | Frequent (1x/6–12m) | 1–2 years | Very High | Rusts easily; needs constant treatment |

| Regular Plastic Boards | Mediocre | Moderate (1x/1–2y) | 1–1.5 years | Medium | Brittle; fades quickly in sunlight |

The facts are clear: what UHMWPE facings for rubber fenders offer is longer life with far fewer headaches and considerably lower life-cycle costs compared to traditional liners. For cost-effective ROI from day one, strategically under-staffed ports looking to do more with less is inarguably a no-brainer investment.

Why Can’t Ports Get Enough of UHMWPE for Rubber Fenders?

While rubber fenders are mandatory for port safety, traditional rubber fenders do not work well in busy and/or tough condition environments. UHMWPE solves every one of those problems and turns rubber fenders from a maintenance burden to a set and forget asset. Here is what is driving the shift for ports across the Globe:

1. Reduction of Maintenance and Downtime Costs

The most significant potential benefit associated with UHMWPE facings? They extend the serviceable lifespan of rubber fenders by 3-5 folds. Their ultra-smooth surface stops the attrition that degrades traditional fenders due to extreme friction, inducing cracks, peeling, and deformation. What used to require annual replacements, now requires attention every 3-5 years, saving the port thousands in material costs and unspent downtime.

2. Tough Enough for the Toughest Ports

By nature, ports cannot control the situations they face. Whether it is 10,000-ton vessels hitting berths or extreme cold winters in the polar region, rubber fenders need to function without fail. The UHMWPE toughness requires no mitigating.

The full extent of large ship impacts is absorbed enabling protection of both the dock walls from structural damages and the ship hulls from expensive scratches, ensuring a win-win for port operators and shipping companies. UHMWPE is the only rubber fender that retains it’s flexibility at extreme cold of -70 ̊C, unlike conventional fenders, which become brittle and crack at a cold of -20 ̊C or less. Polar ports that previously struggled dealing with obstacles in winter now have no fear of fender failures — no costly anti-freeze treatments or fender replacements.

3. Corrosion-Proof

Salt spray, acids, and seawater—these are the silent killers of port equipment. Standard fender liners rust, deteriorate, and eventually leak over time, creating safety issues and shortening the lifespan of the equipment. However, UHMWPE is completely unaffected by corrosion. It can be submerged in seawater for decades without deteriorating. It also resists the harsh chemicals encountered at oil and chemical terminals.This means oil ports and chemical fender systems can never be at risk for fender degradation that results in leaks or contamination.

4. Simple Installation and Maintenance

Ports want no trouble with lengthy, disruptive upgrades, and UHWMPE is designed to meet these needs. They are light enough to be carried by hand, easy to cut with simple tools, and can be bolted to existing rubber fenders without altering the dock’s configuration. There’s no need for heavy cranes, specialized crews, and stopping operations to finish the job.

How to Choose the Right UHMWPE for Your Rubber Fenders?

Not all UHMWPE is created equal which is why picking the right specifications is crucial for optimizing the benefit of the fender upgrade. Below is a brief site-specific guide for an easy decision:

1. Choose the Correct Molecular Weight

Inland Rivers/Small Fishing Ports: Where vessels are below 1k tons and only small to medium impacts are expected, we recommend a 3-5 million molecular weight UHMWPE. It is cheap and highly durable.

Large Commercial/RO-RO Ports: Where vessels are 10k tons and up and dock frequently, 9 million is the only option. It is top tier for high impacts, repeated and excessive sliding, and is the most wear-resistant of all grades.

Cold/Extreme Climates: Where temperatures are very low, or if there are substantial fluctuations in temperature, the preferable UHMWPE is at least 1.5 million molecular weight. It retains its strength and flexibility. With ultra-low water absorption (<0.01%) it ensures stability with prolonged exposure to seawater.

2. Get the Thickness & Size Right

Thickness depends on your port’s specific conditions—use this quick guide to match your needs perfectly:

| Operational Scenario | Impact Energy | Ship Tonnage | Fender Reaction Force | Recommended UHMWPE Thickness | Supporting Requirements |

| Small ships, slow docking | ≤50kJ | ≤500 tons | ≤100kN/m | 10mm | Direct attachment to fender |

| Medium ships, regular docking | 50–100kJ | 500–5,000 tons | 100–300kN/m | 15mm | 3mm rubber cushion (for extra buffer) |

| Large ships, faster docking | 100–200kJ | 5,000–10,000 tons | 300–500kN/m | 20mm | Steel front frame (≥12mm) + bolts (≤300mm spacing) |

| 10k+ ton ships, frequent docking | >200kJ | ≥10,000 tons | >500kN/m | 25–30mm | Steel frame + transverse stiffeners (≤500mm spacing) |

In terms of measurements, adapt UHMWPE panels to correspond to the dimensions of the front projection of your rubber fender. Standard base sizes (600×600mm, 1200×1200mm) are suitable for the majority of fenders, but always correspond to your frame or hole drawings to prevent stress points or warping of the edges.

For non-standard fender configurations (arch, V-shape, drum), choose a custom-contoured UHMWPE or a “steel frame + UHMWPE pad” assembly, as this provides even pressure distribution and considerably less friction between the fender and the vessel.

3. Anti-Slip Texture: To Add or Not to Add?

Regular DRY Ports: For smooth UHMWPE wear is the best choice. Its low friction is perfect to minimize docking resistances and ship hull wear. This wear will allow for faster and smoother operational efficiencies.

Rainy/ Slippery Conditions: In the slippery situations, a fine anti-slip a texture of dots or stripes might work, but there needs to be balance. More texture leads to increased shear stress on the fender and ship. If impact damage is the main goal a smooth surface and guide structures is better.

Chemically/ Corrosive Environments: Moist UHMWPE is smooth, corrosion-proof, and other focuses on protecting the steel frames and fasteners with corrosion-resistant marine-grade studs anti. This extends the lifespan of the entire system and complies with an increased level of safety.

Conclusion

UHMWPE facings for rubber fenders are no trend—they’re a permanent upgrade for port operations. They solve the industry’s oldest, costliest pain points: longer life, lower costs, less maintenance, and enhanced safety.

If your port is frustrated by rubber fender repair/replacement costs and revenue losses from damaged fenders, invest wisely. UHMWPE facings deliver noticeable fender performance improvements within months, slash repair/replacement expenses, and immediately boost port productivity—with lasting long-term benefits.

FAQs

Q: How are UHMWPE facings attached to rubber fenders, and will they fall off?

A: Securely bolted on—stainless steel studs (welded to the fender’s steel plates) fasten the panel with anti-loose nuts. Built to withstand repeated impacts, most ports report no detachment even after years of heavy use.

Q: Will UHMWPE deform in hot, sunny climates?

A: No. UHMWPE performs reliably up to 80℃ (ideal for tropical ports) and won’t warp, fade, or soften in sunlight—suitable for all climates.

Q: Is upgrading with UHMWPE more expensive than buying new rubber fenders?

A: No, long-term. Slightly higher initial cost, but 3–5 year lifespan (vs. 1 year for traditional fenders) cuts replacement/labor costs. Most ports recoup investment in 12–18 months.

Q: How often do UHMWPE facings need to be replaced?

A: 3–5 years under normal use: 3 years for high-traffic terminals, 5+ for low-traffic ports. Only regular visual checks (for cracks/wear) are needed—no complex inspections.