Extruded D Fender

D type fender is made of marine-grade flexible PVC, which has excellent durability and low cost. It is also one of the most common fender types.

D fenders are becoming more and more popular due to their versatility and excellent protection. Its installation cost is relatively low, and it can also be cut to the required length. Extruded D fenders are suitable for frame dock, tugs, and other workboats. Smaller bottom width, easy for installation and maintenance. The fenders are available in many other sections as well.

Many of the D fenders manufactured and provided by Boomarine are pre-drilled to ensure even distribution of bolts and greatly reduce installation time. The D fender can also be pre-bent, chamfered and cut to specific length options. We can produce D-type fenders ranging in size from 150 mm to 3000 mm, and can also be customized to meet the installation requirements of various ships and ports.

Features of D Fender:

- Reasonable reaction force and higher energy absorption.

- Easy to install.

- Lightweight and easy to maintain.

- Rugged design.

- Suitable for frame type wharf, or protection of vessel.

- Applicable for small quays, fishing boats, tugs, barges, and pontoons.

Applications of D Fenders:

- Dinghy docks and piers

- Tugboat and workboat

- Floating bridge protection

- Inland waterway

- General fender

- Boat berth

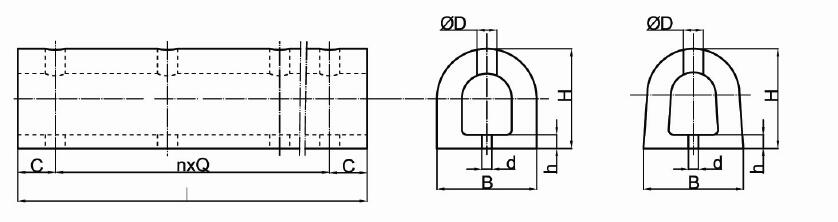

Dimensions: (mm)

| Type | Specification | ||||||||

| H | B | L | holes | Q | C | h | D | d | |

| D150x150x1000 | 150 | 150 | 1000 | 3 | 350 | 150 | 25 | 40 | 24 |

| D200x200x1000 | 200 | 200 | 1000 | 3 | 353 | 150 | 35 | 55 | 30 |

| D200x200x3000 | 200 | 200 | 3000 | 8 | 400 | 100 | 35 | 55 | 30 |

| D250x250x1000 | 250 | 250 | 1000 | 3 | 350 | 150 | 35 | 60 | 30 |

| D250x250x3000 | 250 | 250 | 3000 | 8 | 400 | 100 | 35 | 60 | 30 |

| D300x300x1000 | 300 | 300 | 1000 | 3 | 350 | 150 | 40 | 65 | 32 |

| D300x300x3000 | 300 | 300 | 3000 | 8 | 400 | 100 | 40 | 65 | 32 |

| D300x360x1000 | 300 | 360 | 1000 | 3 | 350 | 150 | 40 | 65 | 32 |

| D300x360x3000 | 300 | 360 | 3000 | 8 | 400 | 100 | 40 | 65 | 40 |

| D400x400x1000 | 400 | 400 | 1000 | 3 | 400 | 150 | 55 | 80 | 32 |

| D400x400x3000 | 400 | 400 | 3000 | 8 | 400 | 100 | 55 | 80 | 40 |

| D500x500x1000 | 500 | 500 | 1000 | 3 | 350 | 150 | 90 | 97 | 45 |

| D500x500x3000 | 500 | 500 | 3000 | 8 | 400 | 100 | 90 | 97 | 45 |

What types of D fenders can we provide?

- DD Type Fenders: The internal hollow part is D-shaped.

- DC Type Fenders: The internal hollow part is O-shaped.

- DO(Wing) Type Fenders: Similar in design to DD fenders, with double wings

- Solid-D Type Fenders: no internal hollow part. The whole piece is solid.

- Delta Fenders: Delta fenders are slightly more angular compared to the standard D fenders

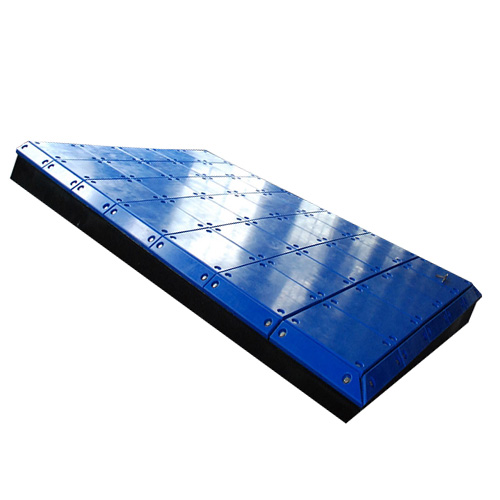

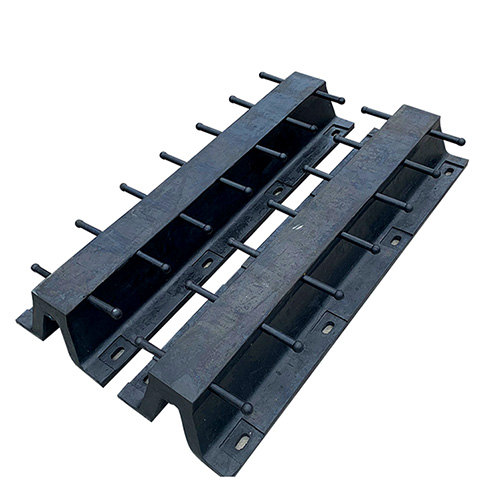

Products Photos: