With the development of the shipping industry, the demand for a wide variety of tugboats is also increasing, resulting in demand for high-quality tugboats. The tug fender requires reliable, stable and high wear in extreme conditions. The tugs are equipped with different types of rubber fenders to achieve maximum protection during operation.

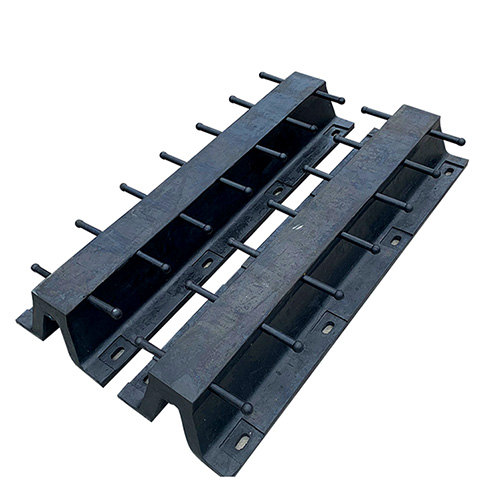

Tug fender is mainly used for all kinds of tugs, installed in the bow, side, and stern of the ship, engaged in pushing, supporting, leaning, and other operations. The fenders use user-friendly fixtures, tools, and slip to make them easy to install and disassemble. With the help of our machine, all tug fenders can be cut into the length and angle required. Mounting holes can also be provided if necessary.

Boomarine manufactured tug rubber fender adopts the integral molding vulcanization process, the overall performance of the product is good, with long service life, and easy installation. As a professional marine fender supplier, Boomarine offers a variety of custom-made tug fenders. With our own production facilities, we can flexibly and quickly produce a large number of high-quality workboat fenders.

Features of Tug Fenders:

- Advanced frame design

- Light and durable

- Easy to install and maintain.

- Absorb huge impact

- Thick wall to wear resistance.

- Progressive load-deflection curve

Applications of Tug Fenders:

- Various tug boats

- Icebreakers

- Work & supply boats

- Other applications & structures like bridge and pile protection

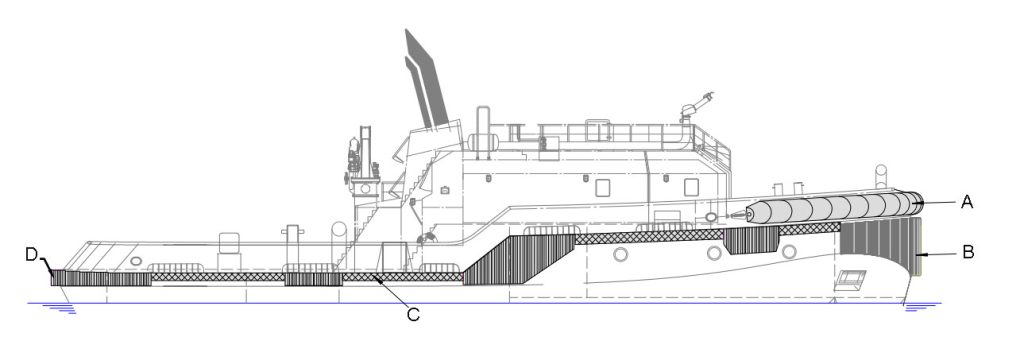

It has four types of tug fenders for special applications:

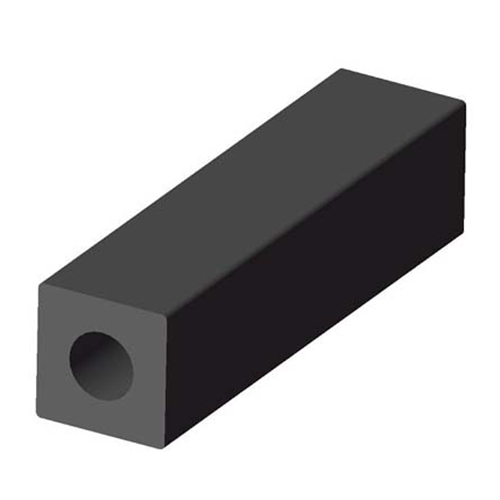

A – Cylindrical Fenders:

Fitted to the bow/stern of tugs and usually used to push against flared hulls and in open sea conditions.

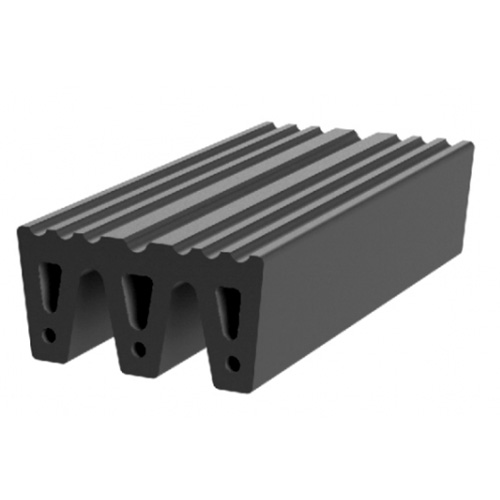

B – Pushing Fenders:

Keyhole, Square, W, and M-fenders provide large contact surfaces for low hull pressures. Their grooved surfaces provide exceptional grip.

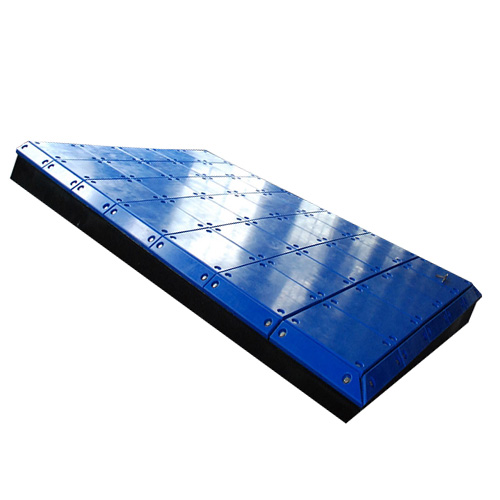

C – Side Beltings:

Square, D, and Composite fenders are often used as side beltings to protect the vessel during escort duties and when coming alongside.

D – Stern of Tugs:

Usually, use cylindrical fenders or any other type.