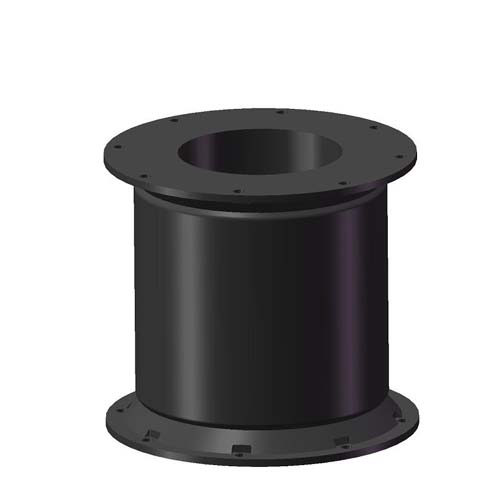

Cylindrical Rubber Fender

- Type: Cylindrical Type

- Materials: Natural Rubber, Styrene-butadiene SBR based compounds

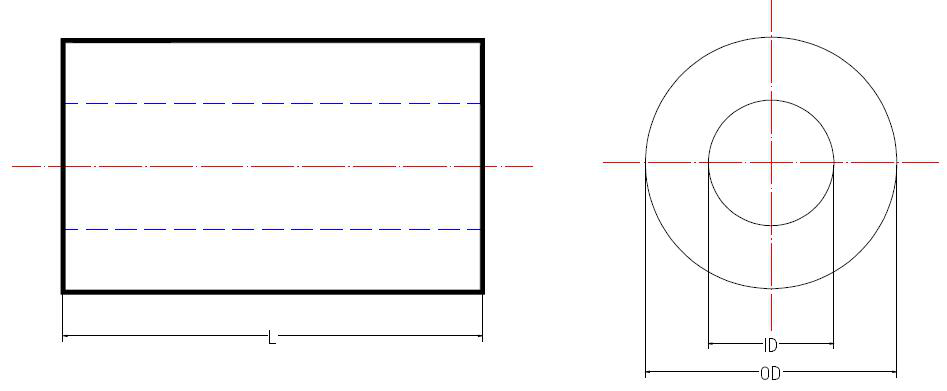

- Outer Diameter: 150mm to 2000mm

- Inner Diameter: 75mm to 1000 mm

- Weight: 16kg – 2994kg

- Color: Black or custom as required

- Certificates: CCS, ABS, BV, LR, KR, etc.

Cylindrical Fender is a simple and multifunctional marine fender system, which is easy to install and usually installed on the hull with a suspension device. This fender is economical and has a thick wall, which can effectively resist wear and tear, and has the characteristics of low reaction force, small pressure surface, and reasonable energy absorption, can withstand huge forces and loads well. Cylindrical fenders have protected marines for more years than any other marine fender types. Their progressive reaction makes them ideal for berths serving large and small vessels special for the upper protection of gravity quay walls.

Generally, we manufacture these cylindrical fenders through molds with extrusion methods, and the size of the fenders can be controlled at any time. They have an outer diameter ranging from 150 to 2000 mm, an inner diameter ranging from 75 to 1000 mm, and a variable length of up to 20 m. As the main push fender. These fenders are usually used in the bow with M fenders or W fenders. Its installation is relatively simple, and it can be installed horizontally, vertically or diagonally with a chain or rod.

As a leading designer and manufacturer of high-performance rubber fenders, Boomarine offers cylindrical fenders in a variety of sizes, and can provide customized solutions to your needs. Our cylindrical fenders are ideal for applications that require protection from large objects and impacts. In addition to this, we also offer other types of rubber fenders. All of our rubber fenders are rigorously tested before delivery and have been certified by classification societies such as CCS, ABS, BV, LR, KR, DNV-GL, NK, RMRS and RINA.

Features of Cylindrical Fenders:

- Low reaction forces, little surface pressure, and reasonable energy absorption.

- Easy to install and maintain.

- Thick rubber walls resist abrasion.

- Simple and economical design.

- Progressive load deflection characteristics.

- Wide range of sizes from 150mm to 2000mm.

- Various installation styles such as horizontal, vertical and diagonal, etc.

Main Applications of Cylindrical Fenders:

- Bulk cargo berths

- General Cargo Quays

- RoRo and Ferry Terminals

- Fishing and Workboat Berths

- Pontoons and Floating Structures

Dimensions & Performance of Cylindrical Fenders:

(Notes: Performance tolerance is ±10%, 50% rated deflection)

Please download the FDF at the top of this page.

| Types | OD (mm) | ID (mm) | Weight (kgs) | Standard Type | High Reaction Force | ||

| Reaction Force (KN) | Energy Absorption (KN-M) | Reaction Force (KN) | Energy Absorption (KN-M) | ||||

| CY150 x1000 | 150 | 75 | 16 | 44 | 1.5 | 73 | 2.3 |

| CY200 X 1000 | 200 | 100 | 39 | 60 | 2.6 | 95 | 4.2 |

| CY250 X 1000 | 250 | 125 | 46 | 75 | 4 | 120 | 6.5 |

| CY300 X 1000 | 300 | 150 | 66 | 89 | 6 | 143 | 9 |

| CY350 X 1000 | 350 | 175 | 90 | 104 | 8 | 167 | 13 |

| CY400 X 1000 | 400 | 200 | 118 | 119 | 10 | 191 | 17 |

| CY500 X 1000 | 500 | 250 | 184 | 148 | 16 | 239 | 26 |

| CY600 X 1000 | 600 | 300 | 265 | 179 | 24 | 286 | 37 |

| CY700 X 1000 | 700 | 350 | 361 | 208 | 31 | 334 | 50 |

| CY800 X 1000 | 800 | 400 | 471 | 237 | 41 | 383 | 66 |

| CY900 X 1000 | 900 | 450 | 596 | 268 | 52 | 430 | 84 |

| CY1000 X 1000 | 1000 | 500 | 736 | 297 | 64 | 479 | 103 |

| CY1100 X 1000 | 1100 | 550 | 890 | 331 | 77 | 528 | 129 |

| CY1200 X 1000 | 1200 | 600 | 1060 | 363 | 95 | 574 | 152 |

| CY1300 X 1000 | 1300 | 650 | 1244 | 392 | 108 | 623 | 179 |

| CY1400 X 1000 | 1400 | 700 | 1442 | 422 | 128 | 670 | 208 |

| CY1500 X 1000 | 1500 | 750 | 1656 | 451 | 147 | 718 | 238 |

| CY1600 X 1000 | 1600 | 800 | 1884 | 481 | 176 | 776 | 282 |

| CY1700 X 1000 | 1700 | 850 | 2127 | 511 | 206 | 824 | 38 |

| CY1800 X 1000 | 1800 | 900 | 2384 | 541 | 247 | 872 | 406 |

| CY1900 X 1000 | 1900 | 950 | 2657 | 570 | 288 | 920 | 487 |

| CY2000 X 1000 | 2000 | 1000 | 2994 | 653 | 321 | 1054 | 584 |

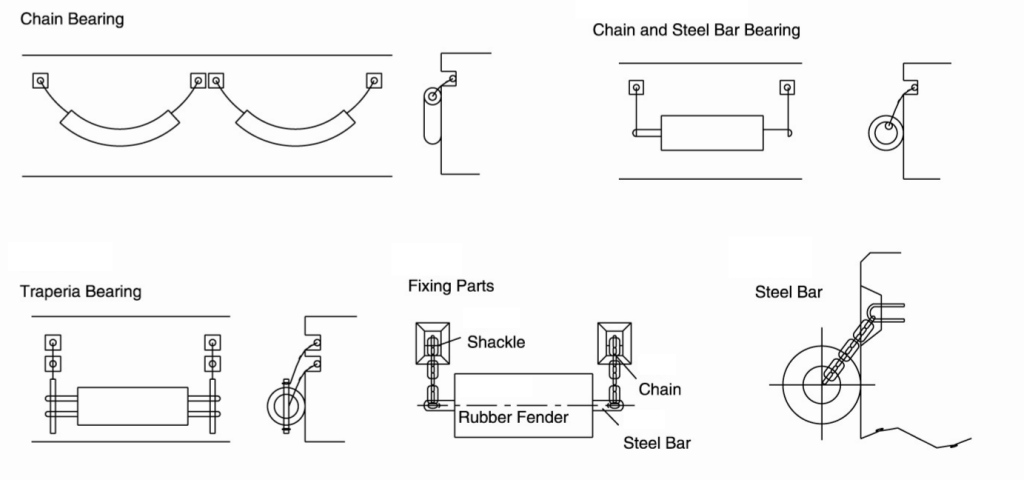

How to Install Cylindrical Fenders?

Cylindrical fenders are hollow cylindrical rubber products, which can be installed in 3 ways according to the fender specifications.

- Suitable for small cylindrical fenders, which can be mounted on the dock with chains and U-rings.

- Suitable for medium cylindrical fenders, fixed to the dock with a steel rod and two shorter chains.

- Suitable for large cylindrical fenders, generally using a steel frame structure to make it more secure and firm.

Installation Methods of Cylindrical Fenders