Table of Contents

Keeping your boat securely anchored is critical for a safe and enjoyable trip on the water. High Holding Power anchors (HHP anchors) as a kind of popular marine anchors provide a dependable solution, but their effectiveness is dependent on more than just their design. This comprehensive guide will teach you how to master your HHP anchor, from choosing the right type for your needs to properly deploying and maintaining it for peak performance. Moving beyond selection, we’ll look at the best practices for using HHP anchors. Mastering deployment techniques ensures that your anchors are set quickly and securely, maximizing their holding power. Understanding proper HHP anchor maintenance is critical to long-term dependability. We’ll provide important guidelines for regular inspections, identifying and replacing worn or damaged parts, and proper cleaning to ensure your anchor is always ready to go. Following the steps outlined in this guide will provide you with the knowledge and confidence needed to master your HHP anchor. This translates to stress-free anchoring, allowing you to relax and enjoy your time on the water while knowing your boat is securely moored.

Choosing the Right High Holding Power (HHP) Anchor

Selecting the right HHP anchor depends on several factors. Here’s a table to help you compare the different types:

| Delta Flipper | Danforth | AC-14 | N Type | TW Type | |

| Design | Fluked anchor with wide, triangular fluke | Fluked anchor with deep shank and wide flukes | Stockless anchor with shank and large fluke | Fluked anchor with large, flat flukes | Fluked anchor with deep shank and a single large fluke |

| Holding Power | Excellent | Good | Very Good | Excellent | Very Good |

| Penetration | Good in various seabed types | Good in sand and mud | Excellent in sand and mud | Good in various seabed types | Good in sand and mud |

| Ease of Use | Easy to deploy and retrieve | Easy to deploy and retrieve | Requires special deployment shackle | Easy to deploy and retrieve | Easy to deploy and retrieve |

| Suitability | Offshore applications, large vessels | Smaller vessels, recreational boats | Sandy and muddy bottoms | Offshore applications, large vessels | Sandy and muddy bottoms |

Additional Factors to Consider

- Seabed Conditions: Delta Flippers and N types perform well in various seabed types. Danforth and TW types are better suited for sand and mud. AC-14s require sandy or muddy bottoms for optimal performance.

- Boat Size: Delta Flippers and N types are ideal for large vessels. Danforth and TW types are suitable for smaller boats. AC-14s can be used in various sizes depending on the model.

- Deployment and Retrieval: Delta Flippers, Danforths, and TW types are easy to deploy and retrieve. AC-14s require a special deployment shackle.

General Recommendations

Delta Flipper or N-type anchors are ideal for offshore applications and large vessels. Danforth or TW anchors are suitable for smaller boats with sandy or muddy bottoms. AC-14 anchors provide excellent holding power in sand and mud, but they require a special shackle. Remember that consulting with a professional anchor manufacturer based on your specific needs and local seabed conditions is always the best option.

Tips for Proper Use of HHP Anchors

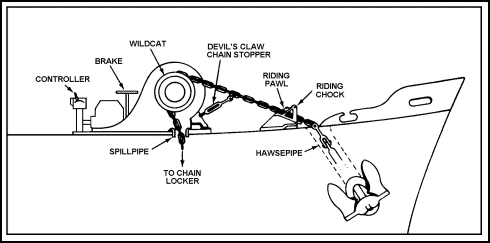

1. Proper Anchor Deployment Techniques

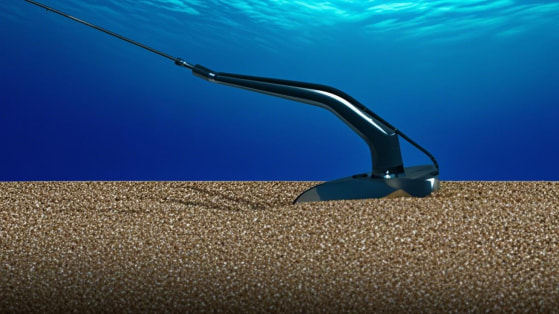

HHP anchors use specific mechanics to dig in and hold. Improper deployment can prevent the anchor from properly setting, resulting in significantly reduced holding power. For example, a Delta Flipper must strike the seabed at a specific angle for its flukes to engage properly. Even the best HHP anchor will fail if it is not installed correctly. Incorrect deployment can result in the anchor dragging across the seabed, putting your boat and crew at risk, particularly in bad weather. Following proper deployment techniques ensures that your anchors are set quickly and effectively, reducing the risk of dragging and the need for multiple attempts. This conserves time, effort, and fuel.

2. Monitoring Anchor Drag and Making Adjustments As Needed

Anchor-holding power can be influenced by the composition of the seabed, wind, current, and tides. Even when the weather appears to be calm, conditions can worsen after deployment. HHP anchors provide more resistance, but they are not immune to these factors. Regularly checking for drag enables you to detect any problems early on. This gives you time to react before the situation worsens, potentially preventing the boat from drifting into dangerous waters or colliding with other vessels. You can keep your boat securely anchored throughout your stay by monitoring it and adjusting the scope (the amount of rode deployed) as needed. This is especially important for extended anchorages or overnight stays. Waiting for the boat to drag significantly before taking action can be risky. Monitoring is a proactive approach that allows for minor adjustments to ensure secure anchoring.

Maintenance Guidelines for HHP Anchors

1. Regular Inspection of the Anchor and Its Components

Even HHP anchors can wear down over time. Regular inspection allows you to detect potential issues such as minor bends, cracks, or corrosion before they become severe enough to impair the anchor’s holding power. If a minor crack or worn component is not addressed, it can grow into a major problem. Early detection through inspection enables timely repairs or replacements, preventing a catastrophic failure during deployment when the anchor is under high stress. A faulty anchor endangers you, your crew, and possibly other boats in the area. Regular inspection reduces this risk by ensuring that your anchor is in excellent condition and ready to perform as intended. Catching small problems early through inspection is far less expensive than dealing with a major anchor failure later. Regular maintenance increases the lifespan of your anchor and ride, saving you money in the long run.

2. Cleaning and Maintaining the Anchor

Anchors gradually accumulate debris such as mud, sand, and seaweed. This build-up can impair the anchor’s ability to properly set and engage the seabed, reducing its holding capacity. Regular cleaning ensures that the anchor performs at its peak capacity. Many HHP anchors, particularly those with moving parts such as hinges or swivels, rely on smooth operation to ensure proper installation. Saltwater and debris can cause these components to seize or corrode, preventing deployment and potentially jeopardizing holding power. Cleaning and lubrication prevent such problems. Exposure to saltwater and harsh marine environments can cause corrosion and wear to your anchor. Regular cleaning removes corrosive elements and allows for the detection of potential damage. Early detection and maintenance can greatly extend the life of your HHP anchor. Cleaning and maintaining your HHP anchor is more than just about increasing holding power; it’s also about ensuring its dependability, functionality, and longevity. This leads to a safer and more enjoyable boating experience.

3. Promptly Replace Worn Or Damaged Parts

HHP anchors rely on specific components to provide maximum holding power. Worn or damaged components can jeopardize this functionality. For example, a bent shank on a Danforth anchor can limit its ability to dig into the seabed. Worn or damaged parts can cause anchor failure, putting your boat and crew at risk, particularly in bad weather. A broken shackle or frayed rope can render even the best HHP anchor ineffective. Ignoring worn parts can result in further deterioration or even complete failure. If a small crack in a fluke is not addressed, it can progress to a larger break. Replacing parts promptly reduces the risk of catastrophic failure. Replacing a small, worn component is usually less expensive than replacing an entire anchor. Early intervention can save money on future repairs or replacements. Most HHP anchor manufacturers recommend regular inspections and prompt replacement of worn or damaged parts. Following these guidelines ensures that your anchor functions properly and maintains its intended level of safety and performance.

Conclusion

Equipping yourself with the knowledge to select, use, and maintain your HHP anchor allows you to take control of your anchoring experience. Understanding the various HHP anchor types and their functionalities allows you to select the one that best fits your boat and typical anchoring situations. Proper deployment techniques ensure that your HHP anchors are effectively set, digging deep into the seabed for maximum holding power. Adherence to proper HHP anchor maintenance practices ensures your anchor’s long-term reliability and performance. Regular inspections, prompt replacement of worn parts, and proper cleaning ensure that your anchor is always in good condition and ready to provide secure mooring when needed.