ISO13797 Cruciform Bollard is a type of ship mooring fittings installed on board, to belay the mooring and towing rope. It is based on ISO standards and is made of high-quality steel tubes and steel plates, suitable for steel wires and traditional ropes, and can be used on decks or docks.

The surface of ISO13797 Cruciform Bollard is treated with a primer, and it can also be galvanized and painted on request. Besides, the surface is coated with an anti-corrosion protective coating, which has a good anti-corrosion performance. Its nominal size ranges from 150mm to 400mm, and weight ranges from 37KG to 165KG. Cause its safe working load is small, ranging from 78kN to 736kN. So it is only used for small ships equipped with steel wire ropes, and is not suitable for large ocean-going sailboats.

As a professional marine equipment supplier, Boomarine provides various types of marine bollards. Like most of our products, we can also provide you with cruciform bollards with complete material certification and IACS grade certificates. At the same time, we also provide a series of customized solutions.

Features of ISO13797 Cruciform Bollards:

- Simple design, good craftsmanship, beautiful and practical.

- The surface is coated with an anti-corrosion protective coating, which has a good anti-corrosion performance.

- All surfaces that are in contact with ropes are smooth.

- Provide OEM service, and a series of customized solutions.

Technical Requirements of ISO13797 Cruciform Bollards:

- Plate: Weldable steel plate with a yield point not less than 235N/mm2.

- Pipe: Weldable steel pipe with yield point not less than 215N/mm2 or equivalent.

- Welding parts have no cracks, scars, holes, shrinkage, or alluvial soil such impact strength and appearance of the defects.

- All surfaces in contact with the ropes shall be free from surface roughness or irregularities likely to cause damage to the ropes by abrasion.

- The cruciform bollards shall be coated externally with an anti-corrosion protective finish.

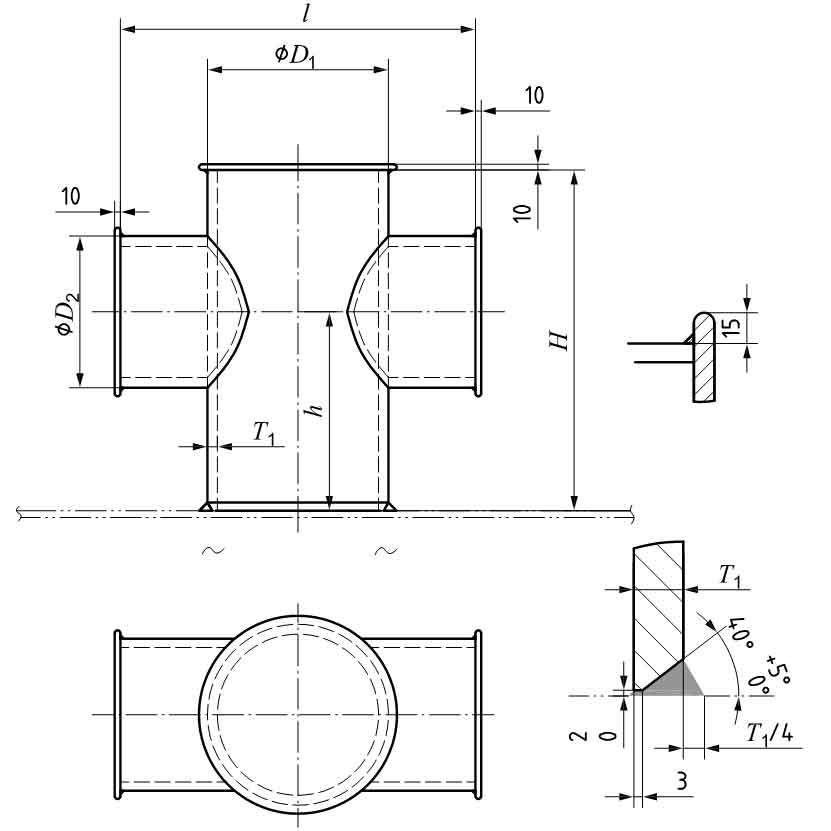

Dimensions (mm)

According to the manufacturing method of the material, ISO13797 Cruciform Bollard should be divided into two types

- Type A: Manufactured by steel tube

- Type B: Manufactured by steel plate

| Nominal Size | Dimensions (mm) | SWL | Weight | |||||||

| DN (mm) | Type | l | D1 | D2 | T1 | H | h | (kN) | (t) | (kg) |

| 150 | Type A | 350 | 165.2 | 114.3 | 11 | 450 | 225 | 78 | 8 | 37 |

| Type B | 350 | 170 | 120 | 8 | 450 | 225 | 78 | 8 | 31 | |

| 200 | Type A | 450 | 216.3 | 165.2 | 12.7 | 500 | 250 | 147 | 15 | 58 |

| Type B | 450 | 220 | 170 | 10 | 500 | 250 | 147 | 15 | 48 | |

| 250 | Type A | 575 | 267.4 | 216.3 | 15.1 | 600 | 300 | 245 | 25 | 92 |

| Type B | 575 | 270 | 220 | 13 | 600 | 300 | 245 | 25 | 81 | |

| 300 | Type A | 625 | 318.5 | 267.4 | 17.4 | 600 | 300 | 392 | 40 | 132 |

| Type B | 625 | 320 | 270 | 15 | 600 | 300 | 392 | 40 | 115 | |

| 350 | Type A | 670 | 355.6 | 267.4 | 19 | 600 | 300 | 491 | 50 | 150 |

| Type B | 670 | 360 | 270 | 16 | 600 | 300 | 491 | 50 | 130 | |

| 400 | Type A | 720 | 406.4 | 267.4 | 21.4 | 600 | 300 | 736 | 75 | 178 |

| Type B | 720 | 410 | 270 | 19 | 600 | 300 | 736 | 75 | 165 | |