Super Cell Rubber Fender

- Type: Cylindrical Type

- Materials: Natural Rubber, Styrene-butadiene Rubber

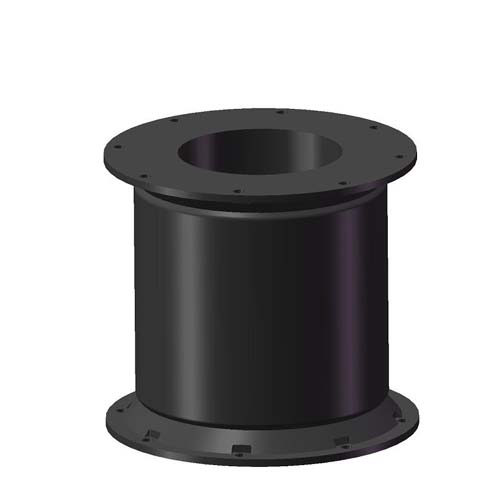

- Diameter: 650mm to 3350mm

- Height: 400mm to 3000mm

- Color: Black or custom as required

- Certificates: ABS, BV, NK, LR, CCS, etc.

Super cell rubber fender also known as SC-type rubber fender, is a kind of rubber fender with ultra-high energy absorption performance, which has excellent multi-direction angular performance with high energy absorption and low reaction force.

The cell fender has a long history and its present structure is the result of continuous improvement. It is available in heights between 400mm and 3000mm and maximum diameters range from 650mm to 3350mm. It can also be customized according to customer needs. This gives it simplicity, high performance, and high strength, but its mounting dimensions have not changed and it is interchangeable with many earlier types of cell fenders. This kind of cell fender has various specifications and sizes to meet various berthing needs.

Compare with general cell rubber fenders, super cell rubber fenders raised design compression by 5%, thus maintaining the reaction force while increasing energy absorption value by about 15%. The frontal panel can greatly reduce the hull pressure, which makes it especially proper for the berthing of a large ship. The frontal panel will be mounted to rubber fender to reduce the surface pressure to ship. And the UHMW-PE pad bolted on the frontal panel can lessen the friction factor between ship and fender and reduce the shear force greatly during ship berthing, therefore prolonging the fender system service life.

Boomarine offers various types of marine rubber fenders, which are made from premium natural rubber and another styrene-butadiene SBR based compound to meet various performance requirements. Our rubber fenders will go through nearly 100 production and quality inspection processes before leaving the factory to ensure that the best quality products are delivered to you. In addition, all our rubber fenders come with approvals from classification societies such as CCS, ABS, BV, LR, KR, DNV-GL, NK, RMRS and RINA.

Features of Cell Fenders:

- High energy absorption, low reaction force

- Good shear resistance

- Highly durable structural design

- Easy to install and remove

- Can support large panels

- Reduce hull pressure

- Multidirectional dispersion of energy

- Minor affection in angular berthing

- Long service life and high efficiency, making it cost-effective

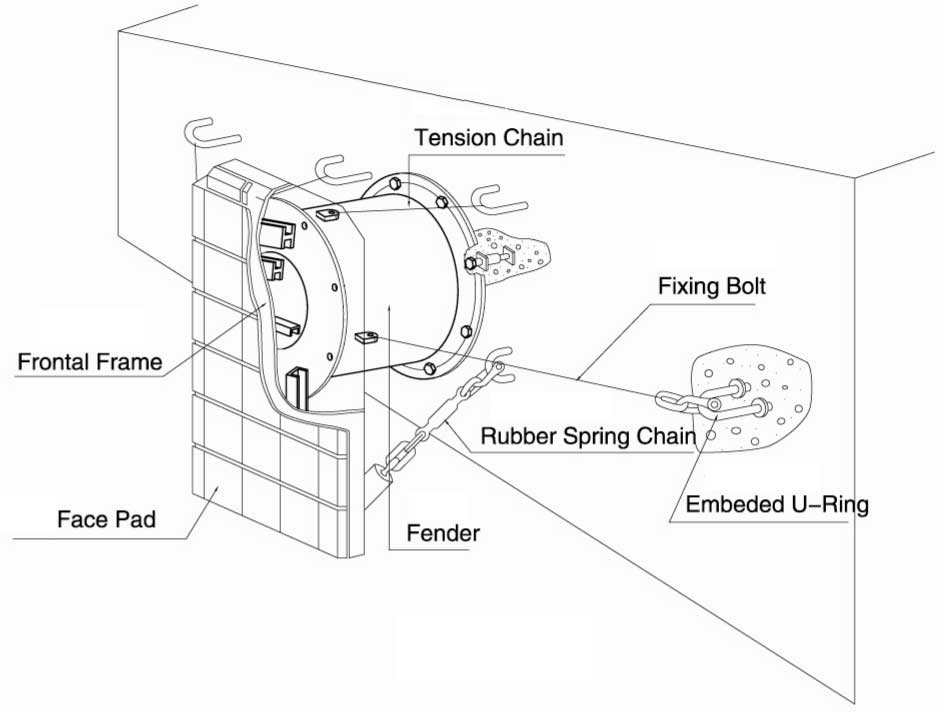

Accessories of Cell Fenders:

- Pre-built in U ring – U-rings are pre-installed in the concrete to hold the chain in place.

- Pre-built-in Bolt & Nut – They are used to fasten the fenders to the dock.

- Chains – Including tensile chain, weight chain and shear chain.

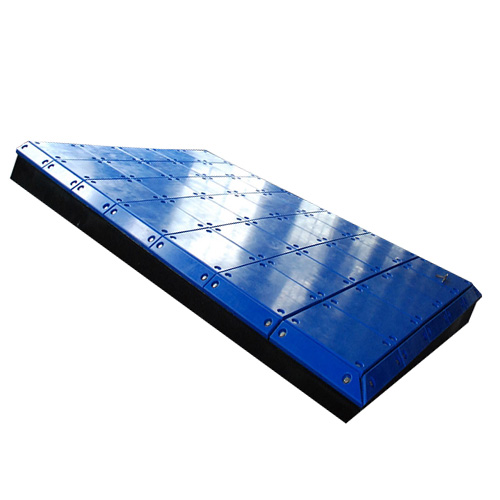

- Front Panel – High pressure is created when the ship approaches the dock. So the front panel is there to reduce surface pressure and avoid damage to the fenders and the boat.

- Face Pad – Reduce the coefficient of friction to protect the hull.

- Connector – Attach the fenders to the front panel and face pads.

- Cell Type Buffer – Absorbs ship shock energy to protect docks and ships.

Main Applications of Cell Fenders:

- Oil and LNG Facilities

- Bulk Terminals

- Offshore Platforms

- Container Berths

- RoRo and Cruise Terminals

- Multi-user Berths

- Ideal for ships with low hull pressure headroom

Dimensions:

(Download PDF at this page for more details)

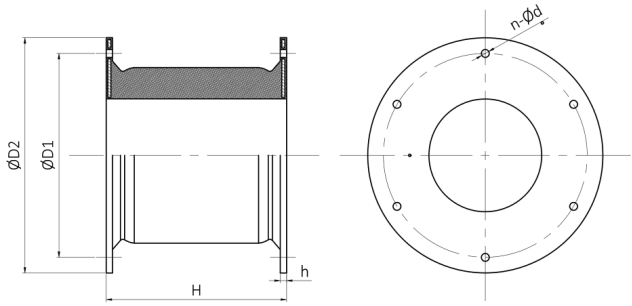

| Type(mm) | H | h | D1 | D2 | n-Φd |

| SC400H | 400 | 25 | 550 | 650 | 4–30 |

| SC500H | 500 | 25 | 550 | 650 | 4–32 |

| SC630H | 630 | 30 | 700 | 840 | 4–39 |

| SC800H | 800 | 30 | 900 | 1050 | 6–40 |

| SC1000H | 1000 | 35 | 1100 | 1300 | 6–47 |

| SC1150H | 1150 | 40 | 1300 | 1500 | 6–50 |

| SC1250H | 1250 | 45 | 1450 | 1650 | 6–53 |

| SC1450H | 1450 | 47 | 1650 | 1850 | 6–61 |

| SC1600H | 1600 | 50 | 1800 | 2000 | 8–61 |

| SC1700H | 1700 | 55 | 1900 | 2100 | 8–66 |

| SC2000H | 2000 | 55 | 2000 | 2200 | 8–74 |

| SC2250H | 2250 | 60 | 2300 | 2550 | 10–74 |

| SC2500H | 2500 | 70 | 2700 | 2950 | 10–74 |

| SC3000H | 3000 | 75 | 3150 | 3350 | 12–90 |

How to install the cell fenders?

This figure shows the way:

Project Photos: