Super Cone Fender

- Type: Cylindrical Type

- Materials: Natural Rubber, Styrene-butadiene SBR based compounds

- Diameter: 750mm to 2700mm

- Height: 500mm to 1800mm

- Color: Black or custom as required

- Certificates: CCS, ABS, BV, LR, KR, etc.

Super cone rubber fender is the 3rd generation product of cell type fender, with a more reasonable structure. Its deflection can reach 72.5% to obtain double energy absorption than other same size fenders. Cone rubber fenders have long service life with a low cost of dock projects. The frontal panel can greatly reduce the hull pressure, which makes it especially proper for the berthing of a large ship. Special for the ports which request low reaction and high energy absorption or all the ports suitable for super cone fender system, its easy to install.

The height of the supper cone fender is available between 300 and 2000 mm, and there are mainly in 3 different rubber grades. Its tapered design provides a large circular base, which can always keep the fender body stable regardless of shear force, axial force or angular force. It’s usually deployed with UHMW-PE pad or steel plate. Super cone fender has an overload stop function, which is more resistant to excessive compression.

As a leading manufacturer and supplier of marine rubber fenders, Boomarine supplied cone fenders are manufactured from high-quality nature rubber and another styrene butadiene SBR based compounds to satisfy various performance requirements. We are not only a professional manufacturer of marine products, but also can customize technical solutions and provide series products. All of our rubber fenders have been certified by classification societies such as CCS, ABS, BV, LR, KR, DNV-GL, NK, RMRS and RINA. If you are looking for the best price supplier of high performance cone fenders, let us provide you with a tailor-made solution!

Features of Super Cone Rubber Fenders:

- Big deflection, high performance

- Stable shape resists shear

- Can support large panel

- Better performance on angel compression

- Wide range sizes, can meet multi-design requirements

- Easy installation

- Excellent energy absorption to reaction force ratio

Applications of the Super Cone Fenders:

- Oil and LNG Facilities

- Bulk Terminals

- Offshore Platforms

- Container Berths

- RoRo and Cruise Terminals

- Multi-user Berths

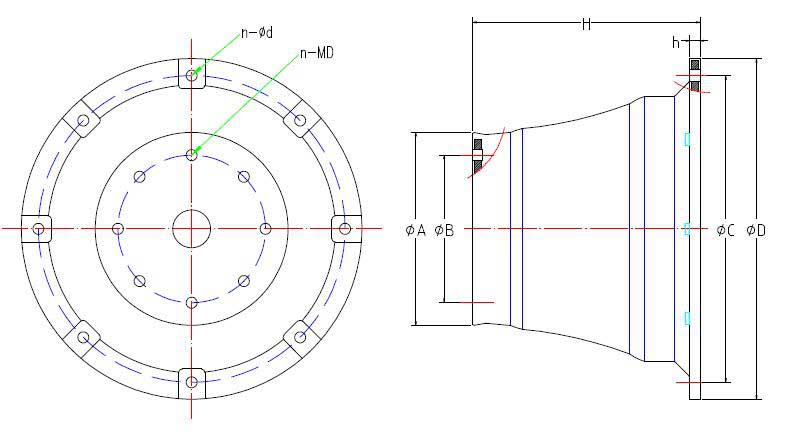

Dimensions:

(Download PDF at this page for more details)

| Type(mm) | H | h | φA | φB | φC | φD | n | φd | MD |

| CN500 | 500 | 25 | 425 | 325 | 675 | 750 | 4 | 30 | M24 |

| CN600 | 600 | 27 | 510 | 390 | 810 | 900 | 6 | 30 | M24 |

| CN700 | 700 | 32 | 595 | 455 | 945 | 1050 | 6 | 38 | M30 |

| CN800 | 800 | 36 | 680 | 520 | 1080 | 1200 | 6 | 44 | M36 |

| CN900 | 900 | 41 | 765 | 585 | 1215 | 1350 | 6 | 44 | M36 |

| CN1000 | 1000 | 45 | 850 | 650 | 1350 | 1500 | 6 | 56 | M42 |

| CN1100 | 1100 | 50 | 935 | 715 | 1485 | 1650 | 6 | 50 | M42 |

| CN1150 | 1150 | 52 | 998 | 750 | 1550 | 1725 | 6 | 56 | M42 |

| CN1200 | 1200 | 54 | 1020 | 780 | 1620 | 1800 | 8 | 50 | M42 |

| CN1300 | 1300 | 59 | 1105 | 845 | 1755 | 1950 | 8 | 60 | M48 |

| CN1400 | 1400 | 66 | 1190 | 930 | 1890 | 2100 | 8 | 60 | M48 |

| CN1600 | 1600 | 72 | 1360 | 1060 | 2160 | 2400 | 8 | 70 | M48 |

| CN1800 | 1800 | 78 | 1530 | 1190 | 2430 | 2700 | 10 | 76 |

M56 |

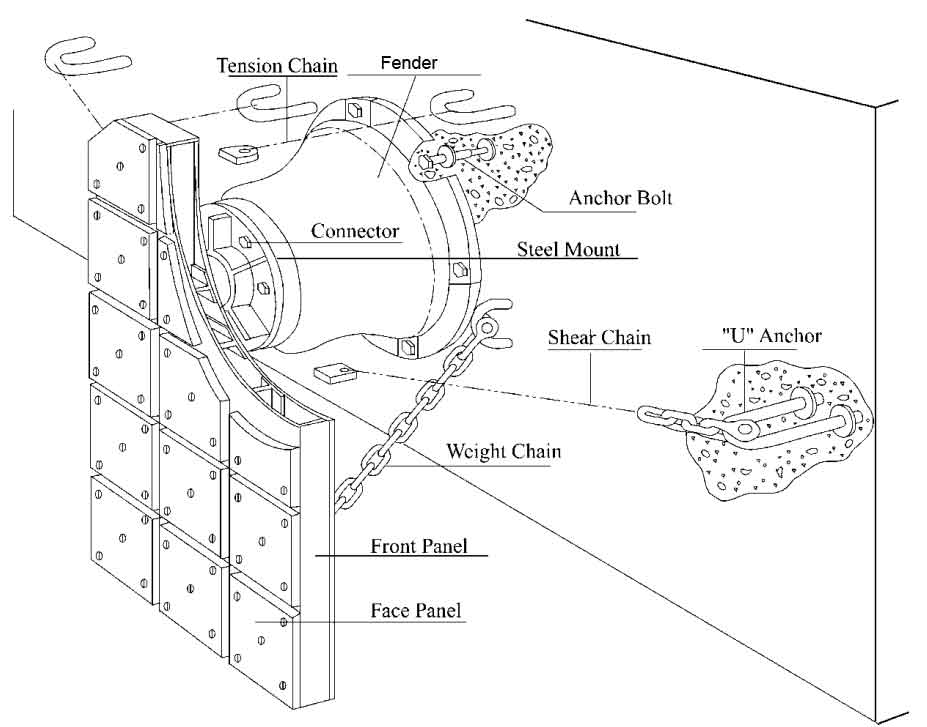

How to install a cone fender system?

This figure shows the way:

Mounting Accessories

- Front Panel: Reduces surface pressure and avoids damage to fenders and boats.

- Face Panel: Reduce the coefficient of friction to protect the hull. Ultra-high molecular weight polyethylene.

- Pre-installed Bolts and Nuts: Used to secure the fender to the dock. 1Cr18Ni9Ti, SUS304, SUS316 stainless steel or Q235 hot dip galvanized.

- Preset U-Rings: Secure the chain. Q235 painted or hot dip galvanized.

- Anchor Bolt: Connect accessories such as fenders and front panels. Stainless steel (or hot dip galvanized).

- Weight Chain: Supports the front panel to avoid sagging. 1Cr18Ni9Ti, SUS304, SUS316 stainless steel or Q235 hot dip galvanized.

- Tension Chain: When the lower part of the fender is stressed, it limits the deflection of the fender. Q235 hot dip galvanized or painted.

- Shear Chain: Prevents shear deformation of the fender system. Q235 hot dip galvanized or painted.

Products Photos: