Rubber Fenders are a kind of “bumper”, mainly used to protect the hull and mooring facilities from damage when the ship is moored. The fender acts as a shock absorber by absorbing the berthing energy of the ship on the berthing facility. For many people, they may not be aware that large marine vessels have rubber fenders embedded in their outer surfaces. These fenders are also referred to by some as rubber bumpers.

Rubber fenders are also installed on docks. The main purpose of rubber fenders on docks is to absorb collision energy during berthing. It can protect the ship and the dock after a collision.

When choosing the right rubber fender, many service factors must be considered, such as the type of quay structure, the type and size of the ship, the berthing speed of the ship, the berthing method, the sea current and wave action, etc. The following are the top 10 rubber fenders commonly used in docks.

1. Super Cone Rubber Fender

The super cone fender is the third generation of drum rubber fenders. It adopts a new structural design of the conical rubber body and the front steel frame, so that the design shrinkage deformation of the fender is improved from 52.5% without increasing the reaction force. To 70%, it has become one of the best rubber fenders today. Its appearance can lighten the structure design of the wharf and reduce the cost of wharf engineering. It is an ideal substitute for super drum rubber fenders.

The cone rubber fender has been in existence for ten years since its inception, and the design of the cone rubber fender has become a new trend in today’s wharf design and represents a new level of wharf fender design.

Features:

- Compared with the super rubber fender of the opposite specification, the energy absorption is nearly doubled.

- Under the condition that the reaction force and energy absorption of the product are similar, the small size TD-AA cone rubber fender can be used to replace the larger size TD-A super drum rubber fender, and the TD-AA800H cone fender can be used to replace the TD-A1000H fender, reducing the cost of the terminal project.

2. Super Cell Rubber Fender

Super cell fenders have a long history and the current structure is the result of continuous improvement. The front panel can greatly reduce the hull pressure, especially suitable for the berthing of large ships.

Features:

- Improve energy absorption/reaction force value

The E/RH value of super cell rubber fender is about 15% higher than that of ordinary rubber fender. The E/RH value of the side is generally 0.43~0.44.

- The structure is more reasonable

Compared with ordinary rubber fenders, SC rubber fenders have a more reasonable structure. The connection between the fender body and the flange adopts a smooth and over-smoothing, which increases the stress concentration phenomenon of the fender root when it is compressed and deformed. The force of the fender is more reasonable, and the shrinkage of the fender is increased from 47.5% of the ordinary type to 52.5%.

- SC rubber fenders have opposite device bolt hole spacing and bolt holes to ordinary rubber fenders.

- It has the characteristics of little influence on inclined berthing.

3. D Type Rubber Fender

D-type rubber fenders are becoming more and more popular due to their versatility and excellent protection. It is made of marine grade flexible PVC for excellent durability and low cost. It is also one of the most common types of fenders.

Features:

- Reaction force, energy absorption are suitable.

- The width of the bottom is moderate, and the special envoy is suitable for the frame type dock.

- The weight is light and the device is easy to maintain.

- Suitable for small docks, fishing boats, tugboats, barges and pontoons.

4. DO Type Rubber Fender

DO type rubber fender, also known as wing type fender, is a new type of marine rubber fender developed from D type fender. It has a higher reaction force and energy absorption capacity than D type fender. Often used to protect ship walls, docks and harbors.

Features:

- High energy absorption and large reaction force.

- The bottom width is small, especially suitable for frame type docks.

- The device has high strength and long service life.

5. Cylindrical Rubber Fender

Cylindrical fenders are a simple and versatile marine fender system. It has a long history of use, is simple, versatile and easy to install. They are usually mounted on the hull with a suspension and are ideal for boats of all sizes.

Features:

- Low reaction force, small surface pressure, reasonable energy absorption.

- Strong compliance to the roll and pitch when the ship is berthing.

- Wide range of applications, can also be used as anti-collision installation for ships.

- The device is easy to maintain.

6. V Type Rubber Fender

V type rubber fenders, also known as arch fenders, are one of the most popular marine fender systems in the world. The simple design makes it easy to install and reduces the amount of maintenance required. It can be used in limited space or limited height conditions.

Features:

- Moderate reaction force and high energy absorption.

- The device is sturdy and easy to assemble.

- Suitable for medium-sized docks.

7. W Type Rubber Fender

There are installation holes on both sides of the W type rubber fender, and the fender has good flexibility, which can effectively buffer the collision force between the dock and the ship during the mooring and berthing process. It has a unique double “leg” structure with hollows ideal for protecting the mooring portion of a pontoon or bridge pile.

Features:

- The top area of fender is large and the contact surface pressure is small.

- High energy absorption and low reaction force, suitable for wharfs above 10,000 tons.

- The span between the two support arms can be adjusted, and the compression deformation can reach 52.5%.

- The surface layer of the anti-shock plate is ultra-high molecular polyethylene or nylon, and its friction coefficient is small.

- It can be installed vertically or horizontally, and does not need to be equipped with supporting anchor chains.

8. Roller Rubber Fender

The roller rubber fender uses the rotation and compression deformation (rubber) of the roller to absorb the impact energy of the ship. When the ship is berthing or moving, the rotating fender can rotate in accordance with the movement of the hull, thereby ensuring the safety of the dock and the ship. Roller fenders are suitable for use in shipyards, docks, ro-ro wharves, wharf corner guards and places that require limiting the direction of ship movement and berthing speed.

Features:

- The fender (roller) rotates on three axes, which can limit and reduce the speed of the ship, which is conducive to the safe berthing of the ship.

- The compression deformation can reach 40%, which is more than double the energy absorption of the traditional rotating fender.

- Since the roller fender can rotate in accordance with the movement of the hull, there is no sliding friction between the hull and the fender, so it is not easy to damage the hull paint.

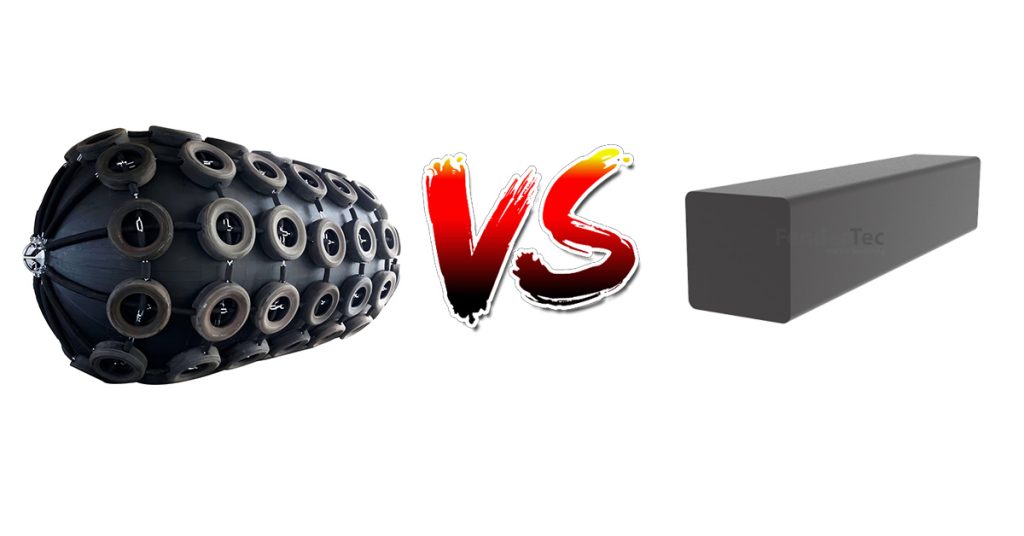

9. Pneumatic Rubber Fender

Pneumatic fender, also known as Yokohama fender, is a common floating fender. It is made of synthetic rope reinforced rubber sheet with compressed air inside with an initial pressure of 50kpa or 80kpa, allowing it to float on the water and act as a shock absorber between the two boats. It is commonly used in seaports at docks and is also used to protect ships during berthing operations.

Features:

- Wide range of sizes.

- High energy absorption, suitable for medium and large docks and ships.

- Not afraid of collision, its friction coefficient is small.

- Easy installation and maintenance.

10. Corner Rubber Fender

Corner fenders, also known as tugboat fenders, are cylindrical fenders used for pushing, racking, extending and sloping operations of various tugboats. Due to their unique design, these tugboat fenders are ideal for protecting round profiles and are typically installed on the bow and stern of the tugboat for port operations, but can also be installed on the side of the tugboat.

Features:

- Excellent resilience performance.

- Easy to install and maintain.

- Excellent resistance to ozone aging and UV resistance.

Choose The Right Rubber Fender Supplier For Your Boat

Boomarine has extensive experience designing and manufacturing high performance, advanced marine fender systems. We offer a full range of rubber fenders for a variety of applications, including use in marine environments such as docksides and piers, dock protection and harbor revetments, and as fenders for most watercraft. In order to provide you with a tailor-made solution for your fenders to meet your specifications, please contact us.